Product details

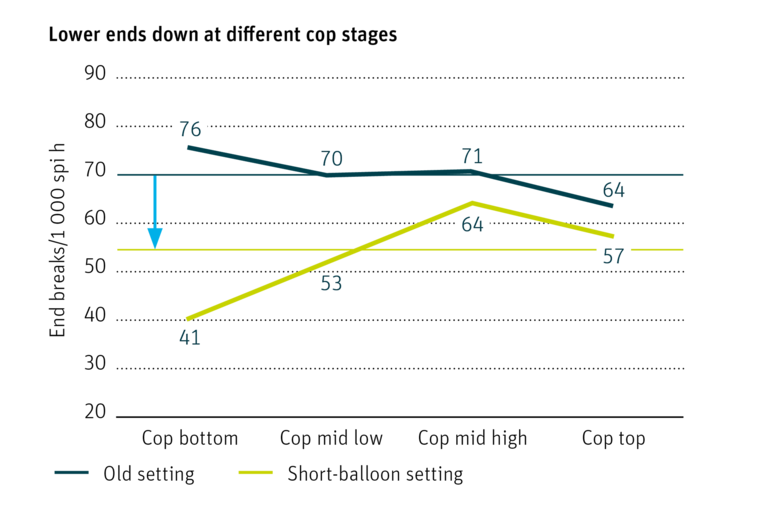

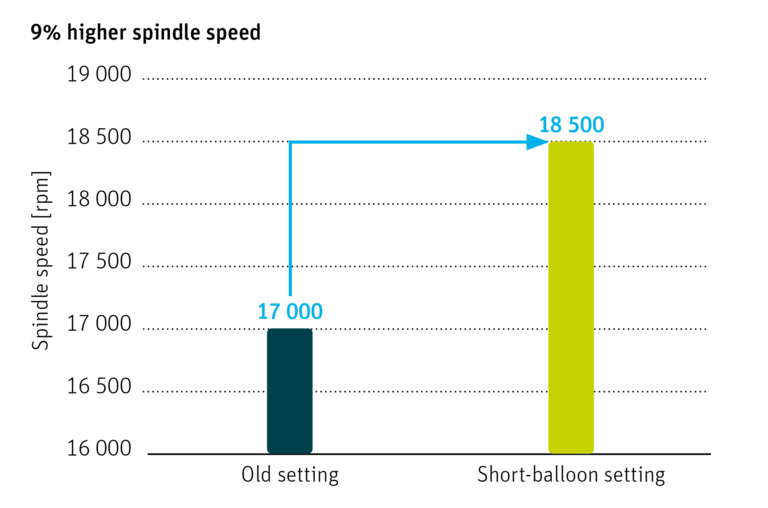

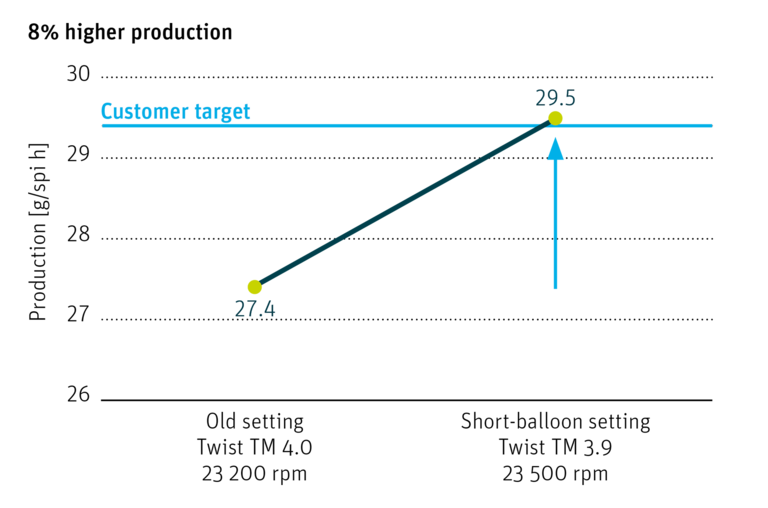

The new Rieter short-balloon setting for ring and compact-spinning machines helps raising the bar by balancing the various balloon forces during cop build-up, thanks to adapted hardware. Trials at spinning mills showed that this brings advantages in terms of up to 10% less ends down rates in average and longer traveler lifetime. Alternatively, the ends down rate can be kept constant, and instead the spindle speed can be increased by 3 to 6%. With an 8% longer traveler lifetime spinning mills save maintenance costs and reduce downtimes.