Com4 Yarns: The Brand

The Brand

The Com4 brand stands for quality yarn that is spun exclusively on Rieter end spinning machines. They meet the highest requirements and ensure competitiveness in a dynamic market.

The advantages of Com4 yarns can be seen throughout the entire production process, from spinning and downstream processing to the final product. These advantages include higher processing speeds, minimized fiber fly and sizing pick-up as well as exceptional pilling resistance and superior wear comfort. The spinning technology is decisive for the yarn characteristic.

The four different spinning technologies ring, compact, rotor and air-jet spinning create four different yarn types:

Com4ring, Com4compact, Com4rotor, Com4jet.

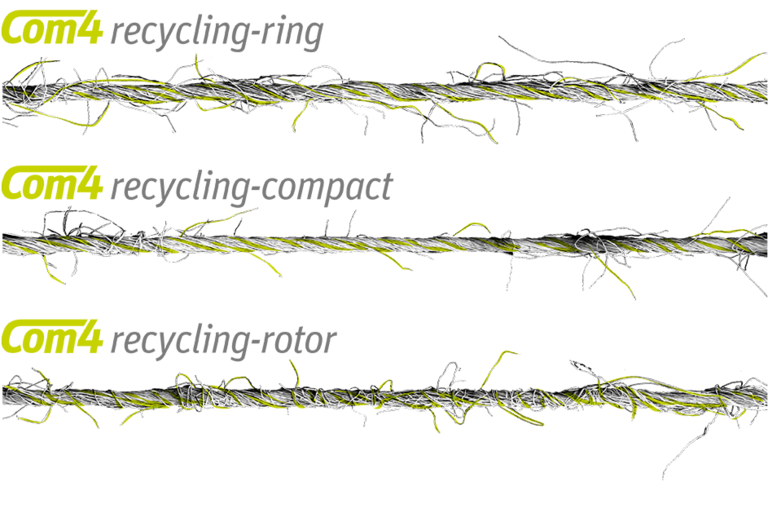

Com4recycling: The license for recycled yarns

In response to the increasing market demand for recycled yarns, Rieter expanded its brand to include environmentally conscious options. The following yarns containing recycled material can be licensed: Com4recycling-ring, Com4recycling-compact and Com4recycling-rotor.

This extension of the Com4 family underlines the commitment to sustainability and reflects the increasing importance of recycled yarns in the industry.

The right yarn for the right application

To decide on the best suitable yarn, the requirements of the final product must be considered. Rieter has comprehensively evaluated important criteria for yarn trader, weaver and knitter. The best suitable yarn will support the quality of the final product and improve the customer satisfaction.

Com4 yarn supplier

In the overview of Com4 yarn suppliers spinning mills are listed that meet the standards of a Com4 license. These globally located mills specialize in the production of a wide range of Com4 yarns, available in different yarn counts and made from a variety of raw materials. Rieter's Com4 licensees benefit from exceptional yarn quality and versatility, giving them a competitive advantage in the industry.