Com4recycling

Com4recycling

With emerging climate change and environmental issues on the rise, the textile industry is now facing its own sustainability challenges. Only 1% of garments are recycled, while a staggering three quarters end up in landfill. However, the share of recycled fibers in short staple fibers has risen in recent years and is becoming increasingly important. Achieving high yarn quality with recycled fibers remains nevertheless a challenge.

Rieter expands Com4 brand: Introducing Com4recycling yarns

In response to the growing market demand for recycled yarns, Rieter extended the Com4 brand. Com4 is a globally registered trademark and stands for quality yarn that is spun exclusively on Rieter end spinning machines.

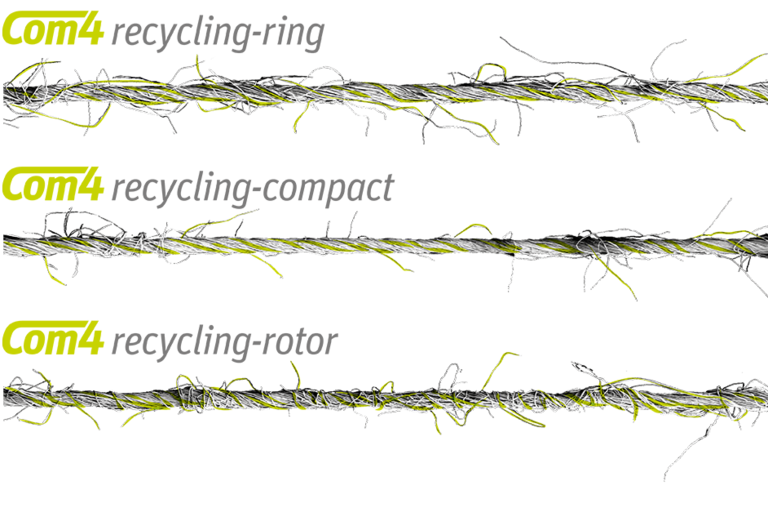

The following yarns containing recycled material can be licensed: Com4recycling-ring, Com4recycling-compact and Com4recycling-rotor. In 2023, our Turkish customer ORTA received the first Com4recycling-ring license – an achievement that was celebrated at ITMA Milan.

To apply for a license, spinning mills must produce their recycled yarn on a Rieter card, draw frame and end-spinning machine. In addition, a Global Recycled Standard (GRS) certification is required.

Sustainable spinning solutions by Rieter: Innovating textile recycling

Rieter is using its technological expertise to offer complete recycling spinning systems for ring and rotor spinning. These processes reflect the current advancements in textile recycling, offering innovative solutions to enhance the sustainability and efficiency of fiber reuse in the textile industry while reaching high quality. Whether utilizing the Com4recycling-ring process, the Com4recycling-compact, or the Com4recycling-rotor, our licensees consistently benefit from high yarn quality alongside economically efficient production.