Revolutionizing Textile Supply Chains with Traceability Technology

Revolutionizing textile supply chains with DNA marker.

Soorty Enterprises has transformed its supply chain by integrating DNA marker technology, ensuring full traceability from fiber to finished garment. In partnership with Rieter and Haelixa, Soorty now meets the rising demand for transparency and sustainability, setting a new standard for trust and authenticity in fashion.

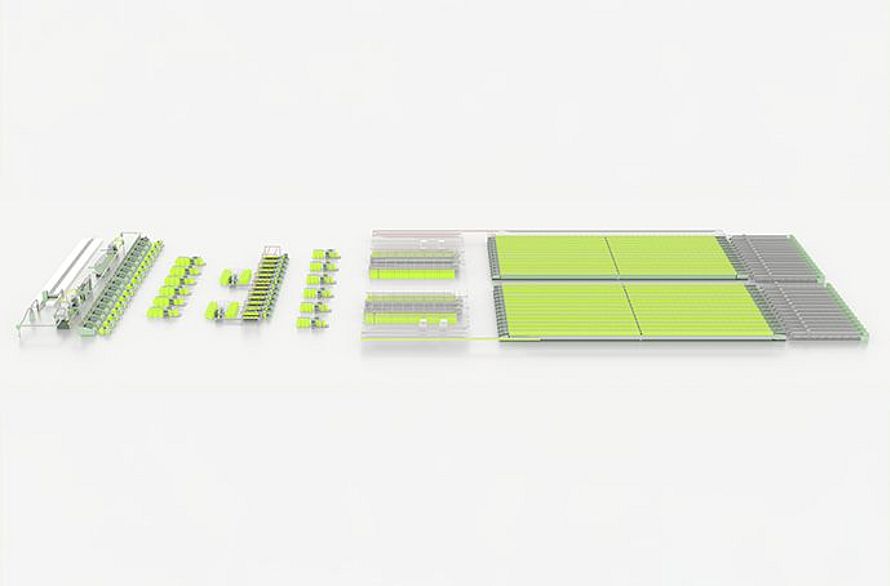

As consumers and fashion brands demand greater transparency in the fashion industry, Soorty Enterprises, a leading global denim manufacturer based in Pakistan, took a pioneering step toward reshaping the future of textile supply chains. Partnering with Rieter and Haelixa, Soorty successfully integrated DNA marker technology into their production processes, ensuring full traceability and authenticity of their products from fiber to fabric.

Meeting growing market demands for transparency

Soorty faced the challenge of meeting growing market demands for transparency and sustainability while ensuring their operations remained efficient. Customers wanted to know not only where their clothes came from but also the ethical standards behind their creation. Soorty needed a solution that could verify the origin of their materials while maintaining the speed and quality of their production processes.

Offering a DNA marker on our products enables us to bring more transparency to our sustainability activities, it shows where and how our products are made, which labor practices are involved. The marker basically reflects the journey of our products from blowroom to the end consumer.Kashif Suleman, Chief Operating Officer at Soorty Enterprises.

Applying unique DNA markers to fibers in the blowroom

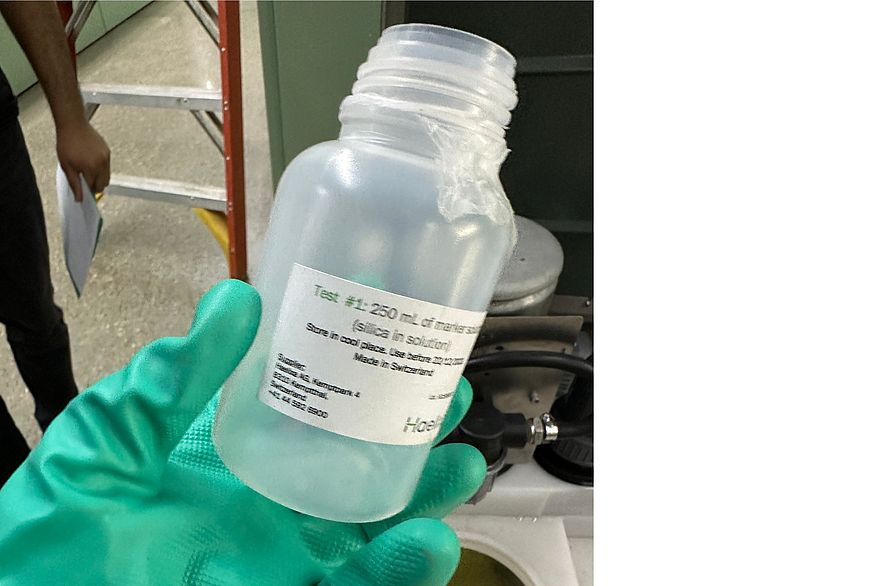

To address these demands, Soorty collaborated with Rieter and Haelixa, two industry leaders in supply chain traceability solutions. Haelixa’ s DNA marker technology offered a solution that could be seamlessly integrated into Soorty’s existing spinning processes. By applying unique, invisible DNA markers to fibers during the initial stages of yarn production, Soorty could create a verifiable fingerprint for each batch of textiles.

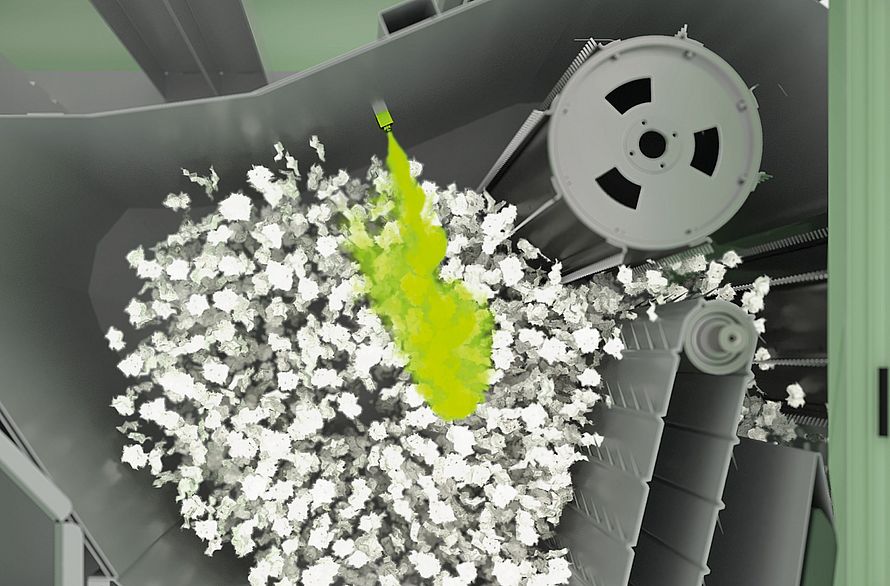

The technology was integrated into Rieter’s fiber mixing machine UNImix B 72, where an automated spraying system distributed the DNA markers uniformly across the fibers. This integration enabled Soorty to mark 20 000 kg of fiber in a single garment order without disrupting their production flow.

The DNA markers remain intact through the entire production process, from fiber blending and spinning to final garment manufacturing. Soorty was able to verify the traceability of the yarn throughout the entire supply chain, delivering a product with complete transparency.

This new capability allowed Soorty to offer customers proof of the ethical sourcing and authenticity of their garments. With a robust traceability solution in place, Soorty gained a competitive edge by providing accurate product information to their clients, reinforcing trust, and positioning themselves as a leader in sustainable manufacturing.

Future plans

Building on this success, Soorty is expanding its traceability efforts. They plan to apply DNA marker technology to their organic cotton grown through their Soorty Organic Cotton Initiative (SOCI), ensuring full traceability from farm to consumer. SOCI aims to transition over 1 000 farmer families in Naal, Pakistan, to organic cotton farming. The project produced its first certified organic cotton bale in 2022 and trains over 100 Balochi women annually through a Rural Women Empowerment Initiative.

Applying traceability technology to the source of spinning will enable Soorty to continue leading the charge towards greater sustainability and transparency in the fashion industry.

Traceability is gaining momentum; it will be an added advantage in selling our products in the future. More traceability and visibility on activities throughout the entire value chain will help in decision making.Kashif Suleman, Chief Operating Officer at Soorty Enterprises.