Description

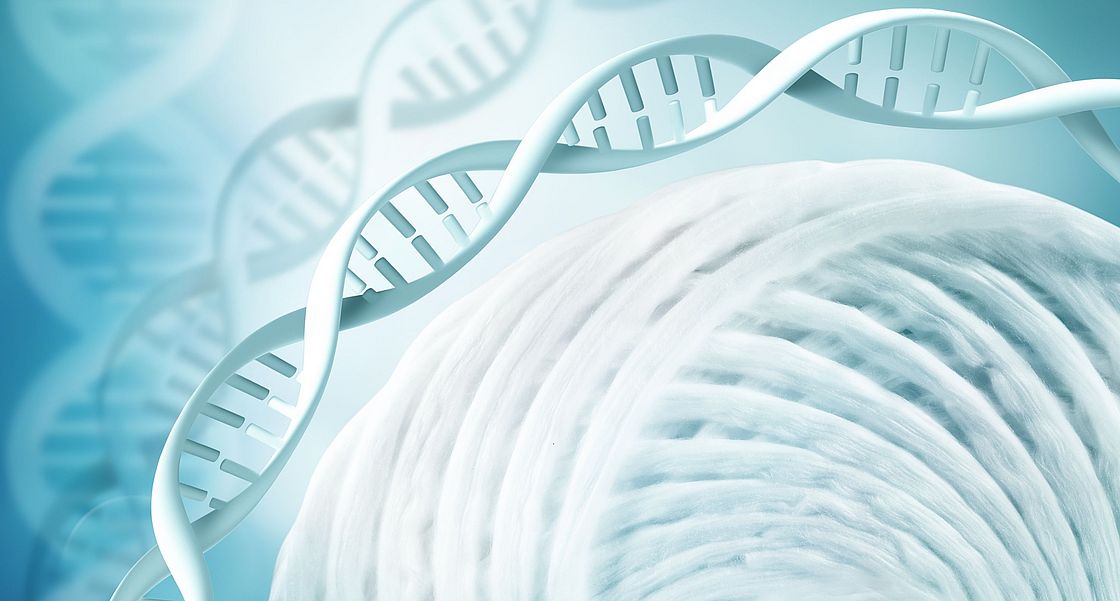

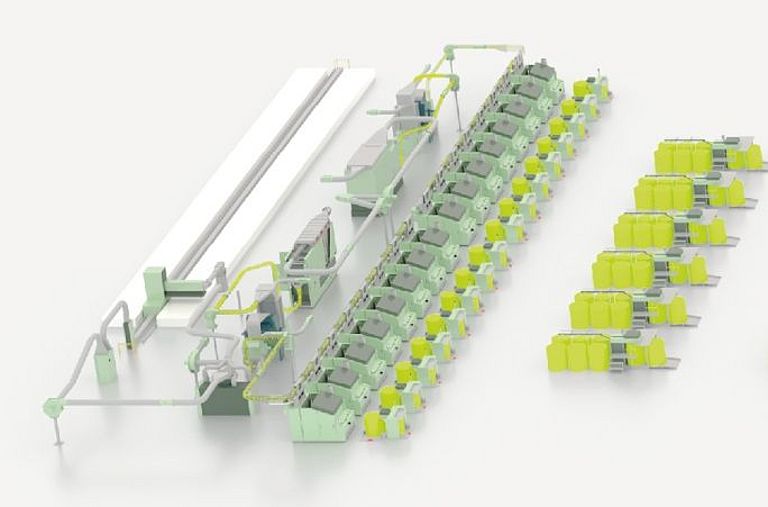

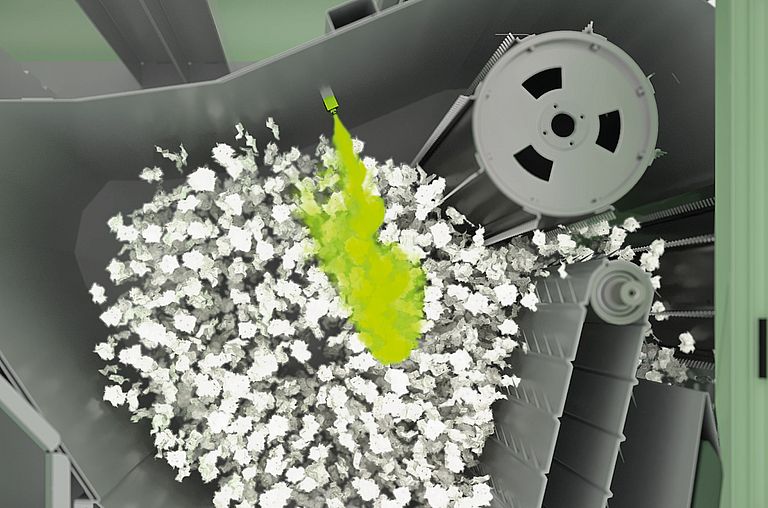

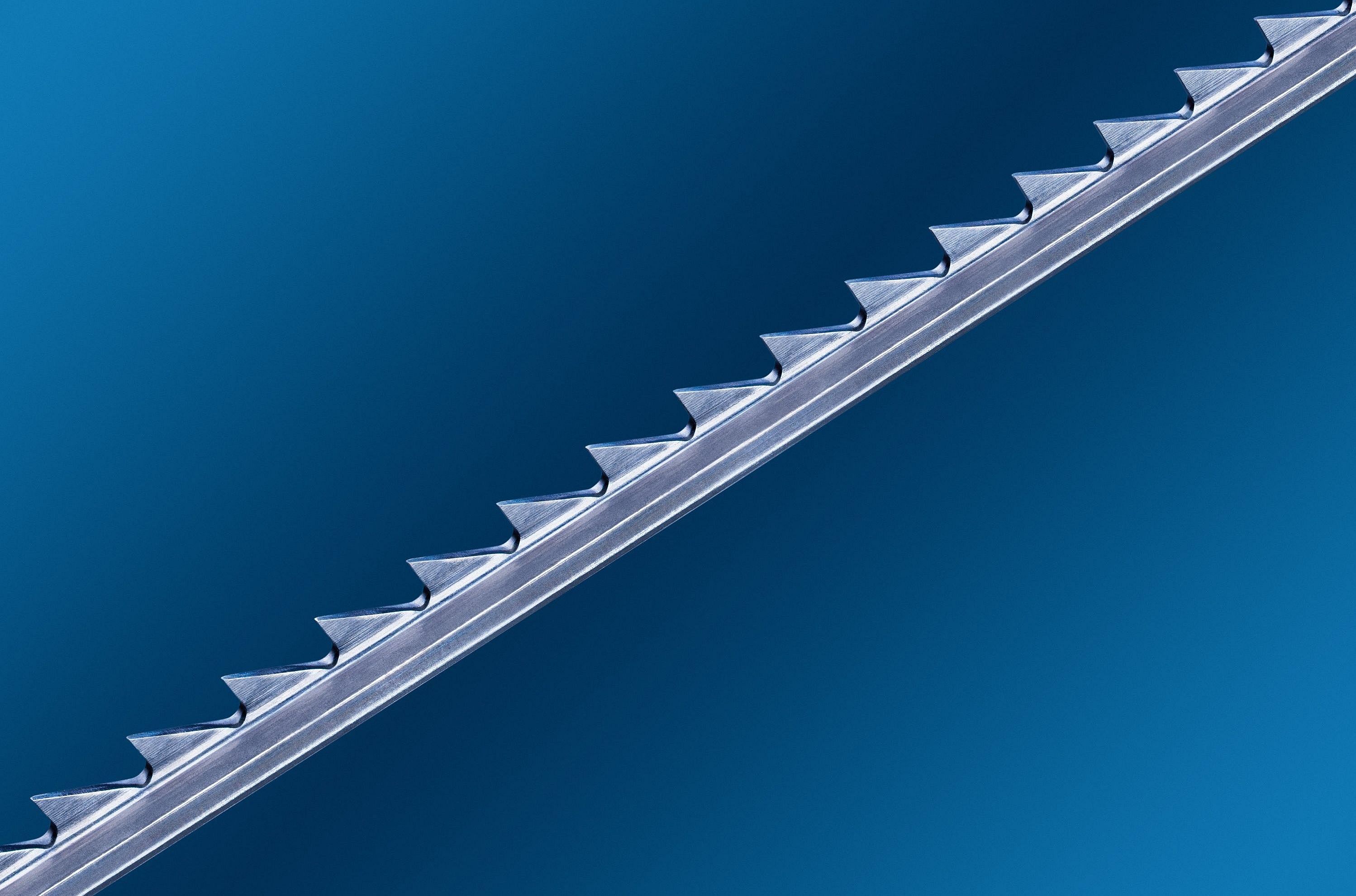

Textile supply chains are known for their complexity and lack of transparency, with manufacturing taking place in fragmented process steps across different geographic regions. However, consumers and fashion brands are increasingly calling for a traceable physical fingerprint to provide forensic evidence of the origin of textile materials, with tightening regulations increasing pressure. Combining Rieter’s expertise in processing short-staple fibers with Haelixa’s technology creates visibility and resilience in supply chains based on a solution that seamlessly integrates into existing spinning systems.