Draw Frame Mini Kit Improves Sliver and Yarn Quality

N Velusamy, General Manager is happy about the performance of RSB-D 22 with the implementation of draw frame mini kit.

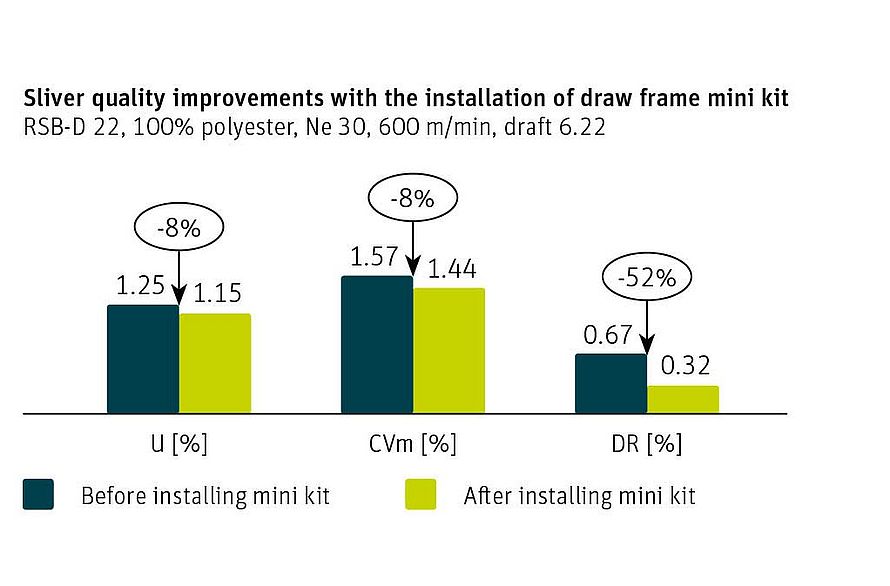

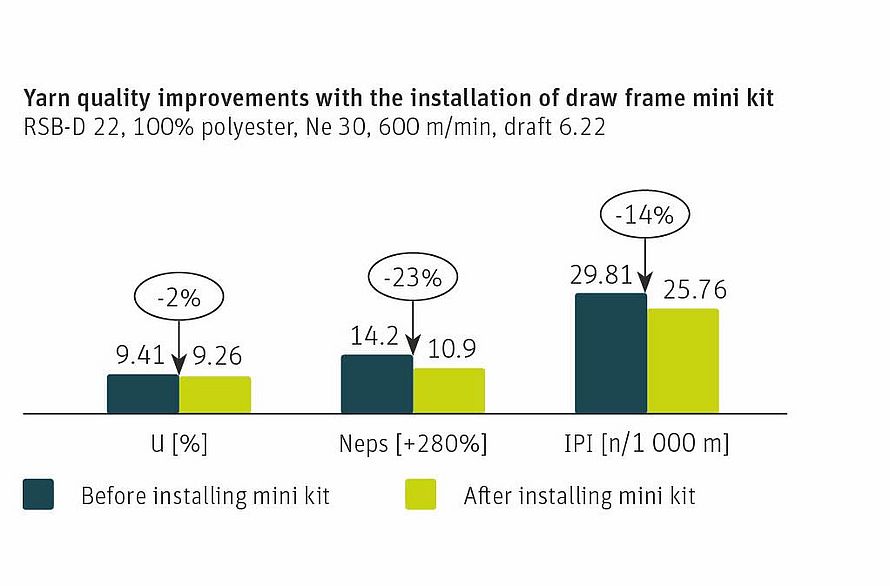

After many years of successful operation, Shri Rohit Spinners Pvt. Ltd.’s autoleveler draw frames were showing signs of wear and tear. They turned to the draw frame mini kit, which helped improve sliver unevenness by 8%, the deviation rate by 52%, and yarn imperfections by 14%.

The Challenge

Shri Rohit Spinners Pvt. Ltd. is a renowned producer of premium-quality polyester yarn. The ageing autoleveler draw frames RSB-D 22 combined with the intense competition in the yarn market prevented the mill from achieving consistent yarn quality. As their machinery aged, Shri Rohit struggled to balance quality control with an optimal maintenance budget. Additionally, the customer encountered difficulties in sustaining machine efficiency, largely due to a reliance on corrective maintenance practices. This situation is common among many mills. A strategic investment in the right parts, however, can provide a sustainable solution, ensuring long-term cost savings and enhanced operational efficiency.

The Solution

Rieter’s after-sales team provided a modular maintenance concept designed to offer a structured and simple maintenance approach. This concept consists of three kits: the mini kit, the performance kit and the overhaul kit. Shri Rohit Spinners implemented the draw frame mini kit to its RSB-D 22 machine. The kit consists of key consumable components from the scanning and drafting zone, which have a lifetime ranging from one to three years depending on the raw material and process parameters.

The aim of the draw frame mini kit is to enhance sliver quality and increase machine efficiency by minimizing machine downtime. Key components like belts, top roller cots, clearer lips, grease and clearer plates are crucial in achieving optimal sliver quality and uninterrupted production.

The Customer's Benefits

Following the installation of the draw frame mini kit on the RSB-D 22 machine, Shri Rohit Spinners experienced a significant improvement in both sliver and yarn quality. Sliver unevenness (U%) and coefficient of variation (CV%) were reduced by 8%. The 52% reduction in deviation rate (DR%) in sliver helps to achieve better yarn evenness, which results in better yarn strength and uniform fabric appearance. Quality improvement in yarn was also observed as the yarn imperfections (IPI) dropped by 14%. Additionally, there was a notable reduction in spectrogram and classimat faults.

The draw frame mini kit is compatible with various models, including RSB-D 50, RSB-D 45, RSB-D 40, RSB-D 26, RSB-D 24 and RSB-D 22. It can be ordered through Rieter’s webshop ESSENTIALorder.

After installing the draw frame mini kit, we saw substantial improvements in both sliver and yarn quality. The reduction in sliver deviation rate and yarn imperfections were remarkable. We thank the Rieter after-sales team for providing this effective maintenance solution.N Velusamy, General Manager, Shri Rohit Spinners Pvt. Ltd., India.

Download

ABOUT SHRI ROHIT SPINNERS PVT. LTD.

Shri Rohit Spinners Pvt. Ltd., India, established in 1996, operates with an installed spindle capacity of 35 000 spindles and a daily production capacity of 21 tons of yarn. Specializing in 100% polyester yarn, the company produces a range of yarn counts from Ne 4.5 to Ne 50. Shri Rohit Spinners is known for its premium-quality yarn, serving both domestic and international markets. In addition, the company produces yarn for sewing thread applications.