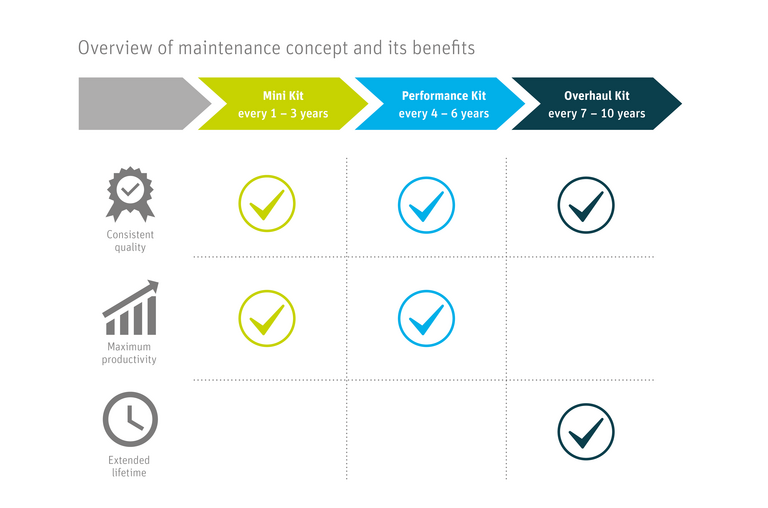

The draw frame mini kit consists of key components in the scanning and drafting zone with more fiber contact and a lifetime of approximately one year. The aim of the draw frame mini kit is to improve the quality of the sliver as well as the productivity. The key components like belts and grease support an efficient power transmission, while the top rollers, clearer lips and clearer plate play a key role in achieving consistent sliver quality. To maintain optimal machine performance, Rieter recommends replacing it every one to three years.

Customer values

- Reducing sliver breaks and roller lapping in drafting

- Improving sliver and yarn quality

- Extending machine and part time