Yarn Clearer Q 30: Key to High-Quality Yarns and Efficient Production

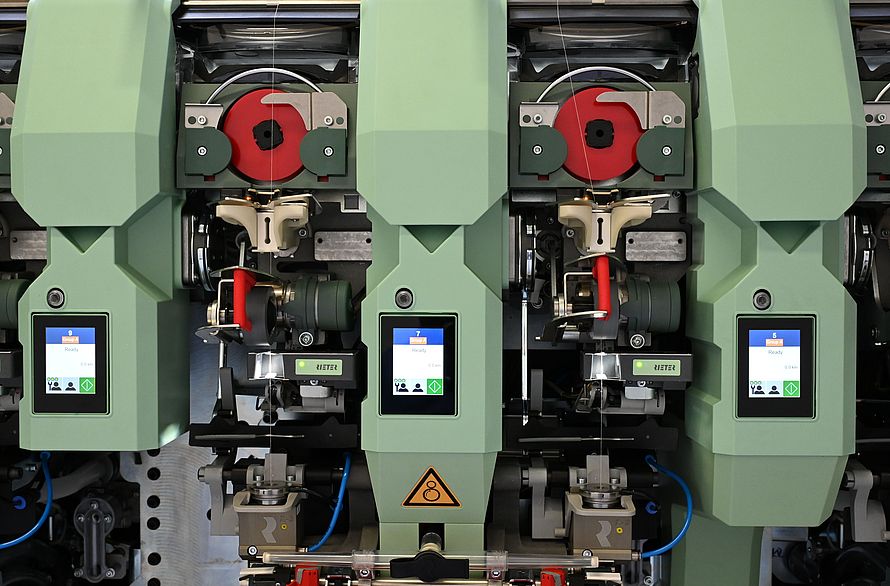

Producing a high-quality yarn with the best downstream properties is only possible with precise yarn clearing. The new yarn clearer Q 30 for the latest Rieter rotor and air-jet spinning machines ensures not only high yarn quality but allows longer production times with less maintenance. The options “foreign fiber detection” and “weak yarn detection” prevent inefficiencies in downstream and guarantee a high fabric quality for weavers and knitters.

The key to producing high-quality yarns is the integration of an advanced yarn clearer into the production process. It detects and removes imperfections and enhances overall production efficiency and profitability. With more than 1.5 million yarn clearers produced during the last 20 years, Rieter introduces the next generation of yarn clearers for the rotor spinning machines R 37 and R 70 and the air-jet spinning machine J 70. The latest yarn clearer Q 30 is characterized by an innovative measuring method.

Increased clearing efficiency and less manual work

The new optical imaging system guarantees a high-resolution measuring of the yarn for a wide range of yarn counts up to Ne 80. With this new system, the yarn structure can be assessed more accurately, which enables better differentiation between yarn faults and non-disturbing events. Thanks to the high-resolution measuring in combination with smart image processing algorithms, the Q 30 precisely detects and removes disturbing faults and finally improves fabric quality. In addition, it increases the clearing efficiency and ensures a better productivity.

Due to the significantly larger measuring slot, the Q 30 is less sensitive to contamination accumulation. The result is longer production times without time-consuming interruptions for the manual removal of fibers in the slot. If this is still necessary, the yarn clearer can simply be cleaned with compressed air.

New option: Weak yarn detection

The new yarn clearer offers unrivaled flexibility for rotor and air-jet spinning machines. The option “weak yarn detection” for air-jet spinning recognizes yarn without or with very low twist and strength. These severe yarn quality problems in air-jet spinning can be caused by contamination, worn-out components or a wrong spinning unit setup. Examples are a chucked fiber feeding element, fluffs in the housing suction hole or damaged spinning components.

The option “foreign fibers” for rotor and air-jet spinning ensures the removal of foreign fibers, such as plastic, synthetic fibers, or natural fibers of different colors. Both options can be ordered with new machines or can be bought later and retrofitted easily through a software update, without replacing the yarn clearer. This allows the spinner to easily adapt to changing requirements.

Easy adjustment of settings

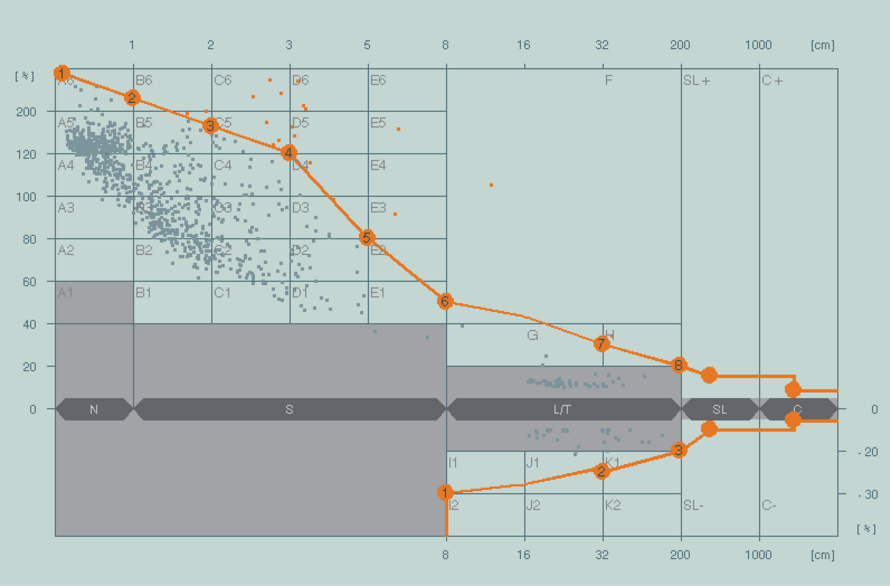

With the Q 30, it is much easier to optimize the settings, and the clearing curve is newly shown in a line without steps. The clearing limit can now be adjusted precisely for each yarn type in accordance with the quality requirements. The spinner can use the scatter plot on the machine panel to see whether the clearing curve is set correctly and optimize it more easily if necessary.