On-site Preventive Maintenance and Repair Enhances Autoconer Efficiency by 10%

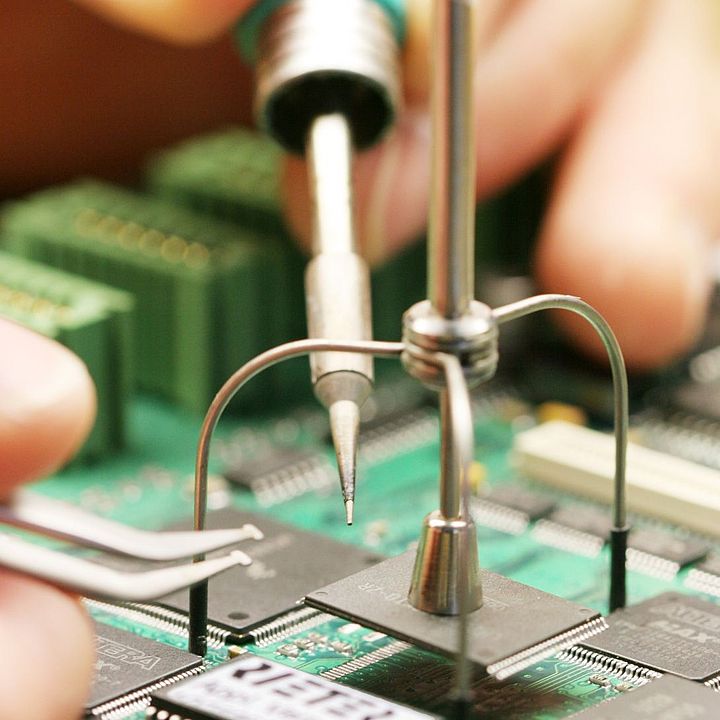

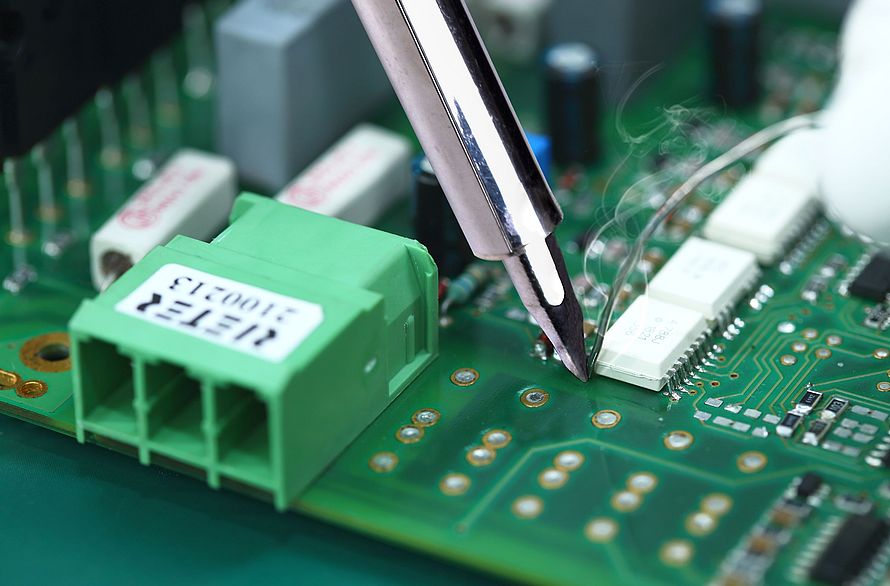

On-site preventive repairs are carried out by Rieter repair service engineers.

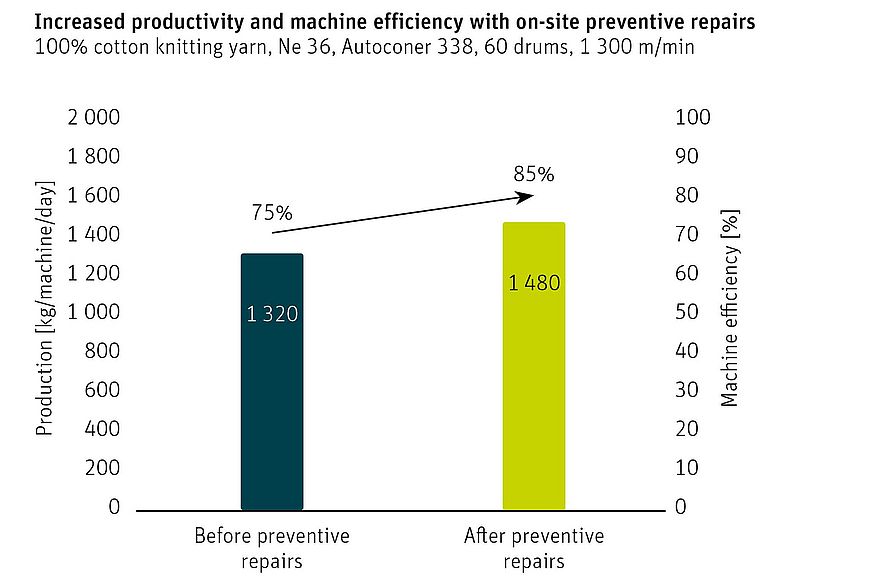

Rieter’s on-site preventive maintenance and repair service for the Autoconer 338 winding machines at Sudhan Spinning Mills, India, has boosted machine efficiency by 10%, leading to increased productivity. Preventive maintenance and repair avoid unexpected downtime caused by component failures, ensuring peak performance and longer lifetime.

The Autoconer 338, a renowned winding machine, has been a cornerstone for many spinning mills over the past two decades. In order to maintain the optimal performance of these machines even after many years, a preventive maintenance service is recommended to monitor electronic control units or other important aggregates in the winding unit.

Economical maintenance and repair service solution for Sudhan Spinning Mills

Rieter’s on-site preventive maintenance and repair service provides both, on-site maintenance and a package of original, high-quality components at a competitive price. For the Autoconer 338, as for other machines, the package includes mechanical and electronic parts, e.g. motherboards, operating units, conveyor drive systems, and doffer boards. Early replacement of such aging parts ensures consistent machine performance and longer machine lifetime.

The preventive maintenance and repair package also reduces downtime due to unexpected component failures, making it a smart investment for customers aiming to enhance the performance of their machines. Leading spinning mills like Sudhan Spinning Mills (P) Ltd. in India have already implemented this solution, achieving a 10% increase in efficiency. Issues like red lights and functional faults have decreased significantly, further boosting productivity and machine longevity.

The advantages of on-site repairs

On-site preventive maintenance and repairs are an economical solution for customers, as they take place at the mill site, saving time and cost associated with transportation and reducing production loss. This preventive work is performed by Rieter repair service engineers, who bring the necessary know-how, special tools and equipment to each site. During the on-site service work Rieter engineers check the running behavior and identify and address operational issues at site. The use of state-of-the-art equipment and original components extend the lifetime of the machine. Additionally, Rieter service engineers provide essential training to machine operators to ensure maximum utilization of the machine.

We have completed on-site preventive maintenance and repairs for our 13 Autoconer 338 winding machines. The machine efficiency has improved which, as expected, leads to increased productivity. Thanks to Rieter for extending the machine’s lifetime.S Jayaraja Perumal, Chief General Manager, Sudhan Spinning Mills (P) Ltd., India.