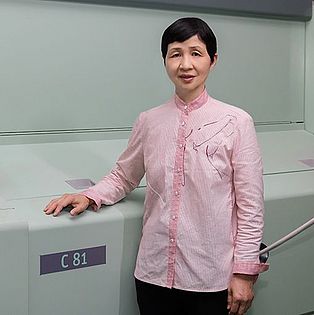

Introducing C 81

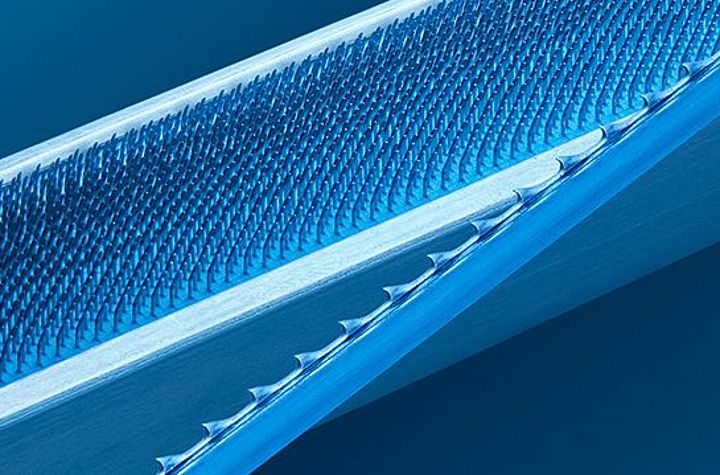

The card C 81 offers the largest active carding area on the market, supported by artificial intelligence. Carding Gap Control ensures a perfect carding gap in all conditions and thus unlocks the full potential of the 40 active flats. The card C 81 produces up to 40% more than any other card with an excellent sliver quality.

With the unique Trash Level Monitor, the trash level is always under control and fiber yield can be optimized. Sensors in the card infeed and after sliver formation analyze in real-time the material quality. The C 81 is also the most energy-efficient card on the market.