Product details

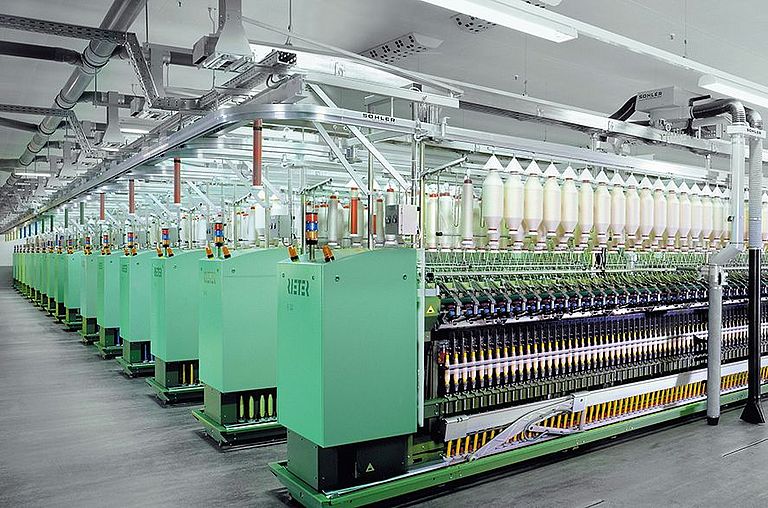

The modular roving bobbin transport system SERVOtrail provides optimal material flow between the roving frame and the ring or compact-spinning machines. It reduces personnel requirements, increases machine efficiency, and ensures excellent roving quality. SERVOtrail saves space, shortens distances for the operators and ensures that the spinning machines are freely accessible.