Innovation in recycling

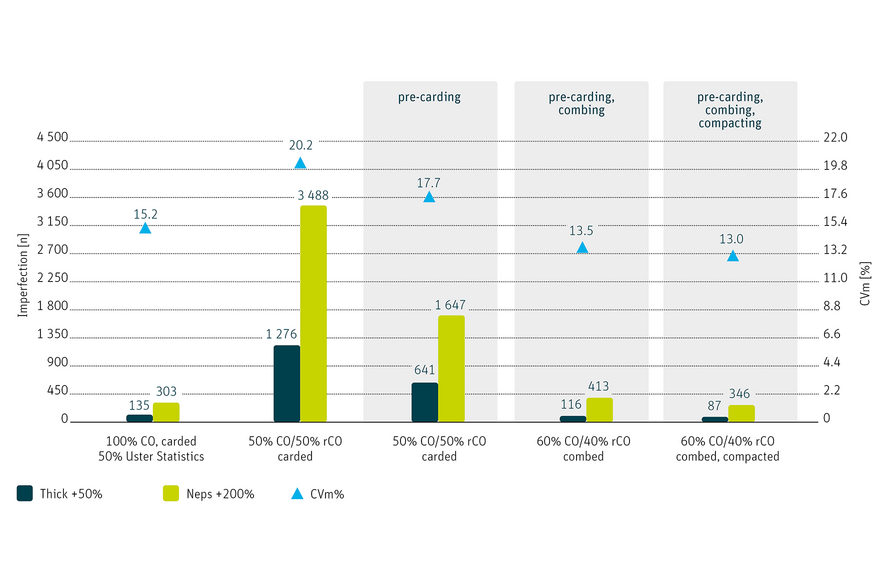

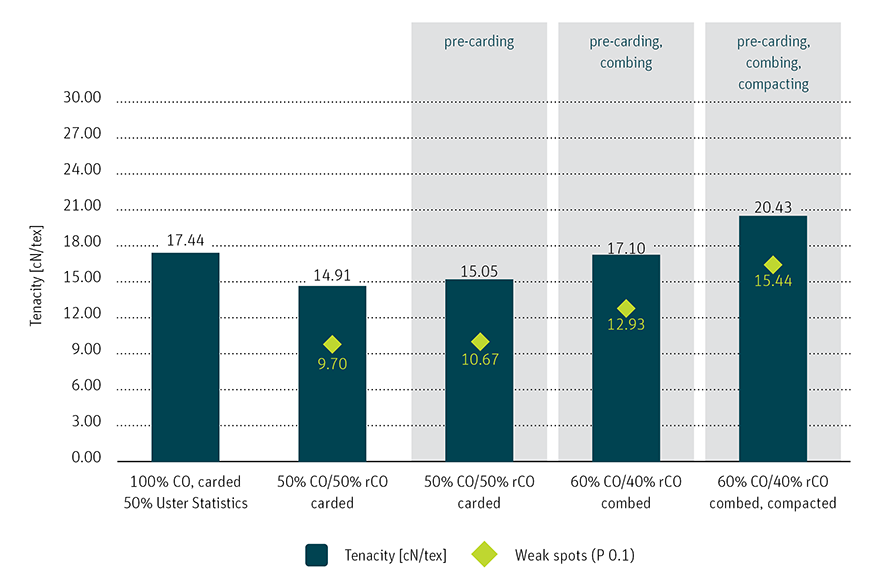

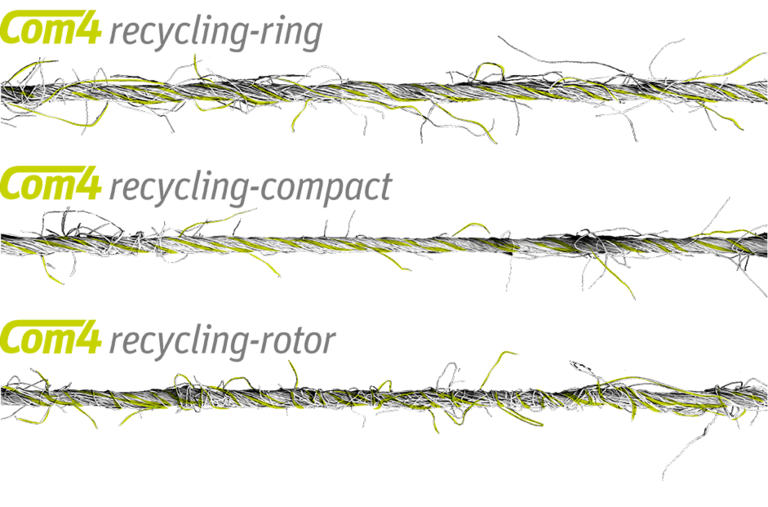

Spinning fine ring yarns with a high share of recycled fibers at a quality level that is comparable to 100% virgin cotton carded ring yarns is possible with Rieter’s recycling toolbox. Each tool contributes to another yarn quality criteria. Trials confirm that pre-carding cleans the recycled fibers perfectly before they enter the spinning process, combing removes very short fibers and compacting adds the finishing touch to the yarn.

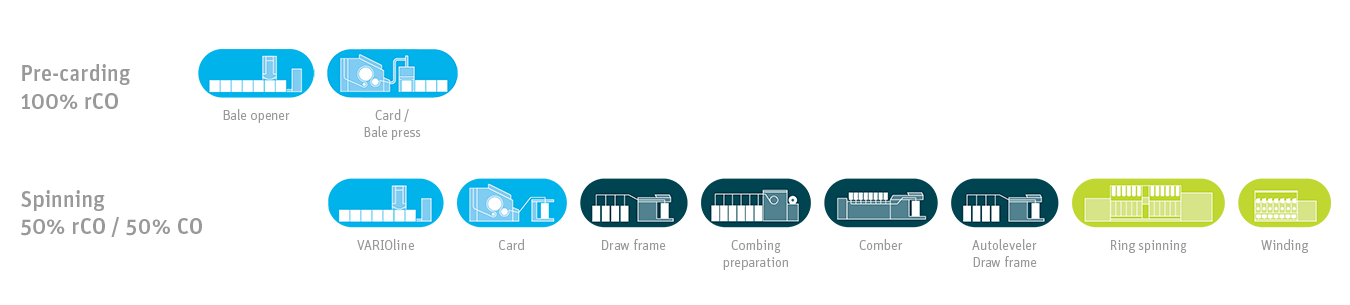

To show the impact of the different tools, Rieter conducted a trial with a blend of 50% mechanically recycled fibers and 50% virgin cotton, spun into a ring yarn with yarn count Ne 30. A regularly spun carded cotton ring yarn, which corresponds to 50% Uster Statistics, serves as a reference. To come as close as possible to the virgin cotton quality, the toolbox comes into play.