Product details

The use of ceramic discs has always dominated the production of Polyamide as there is no difference between Polyurethan and ceramic discs in terms of yarn quality with heavy dtex. Until now, PU discs have been very rarely used in PA texturing due to the shorter service life of PU discs.

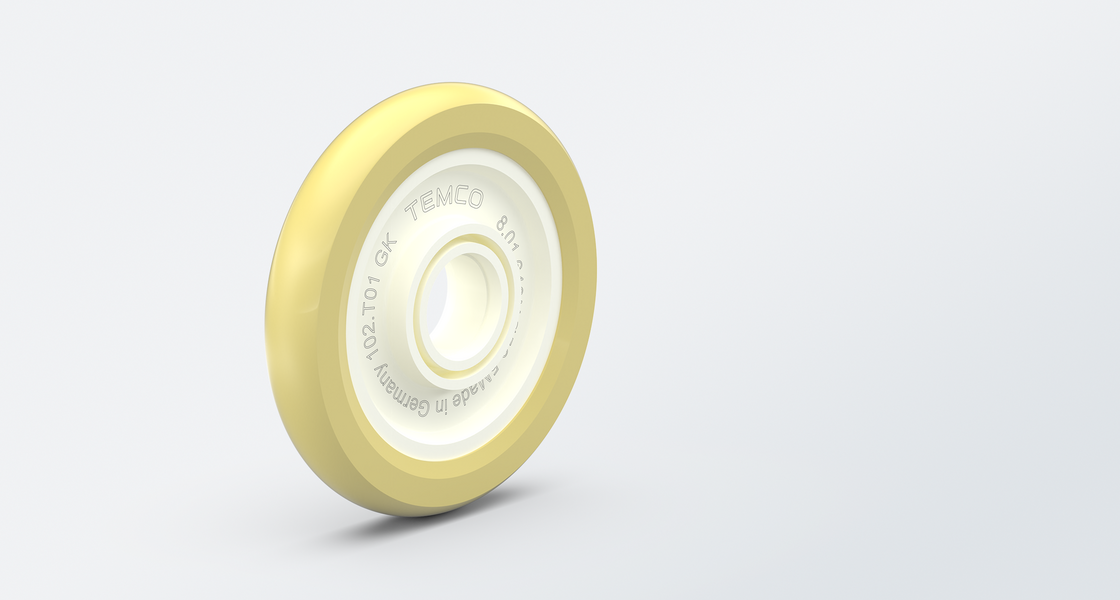

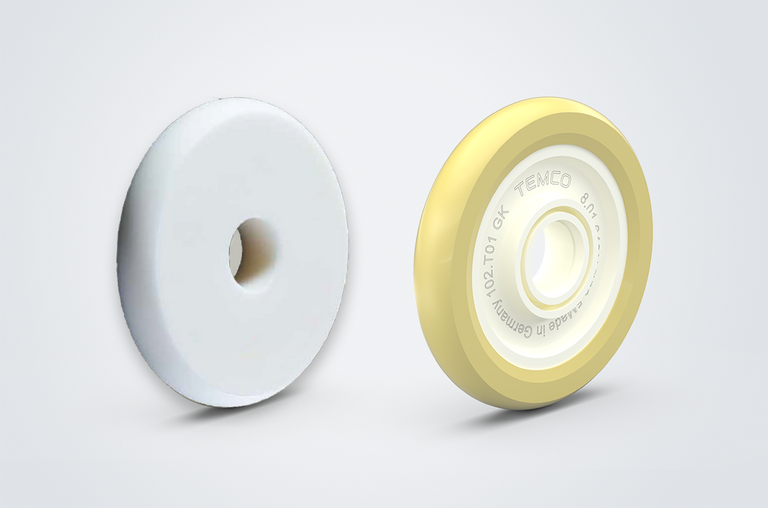

The main problem regarding the service life of PU discs is not wear, as is common in PES production, but the polishing of the surface, which makes threading the yarn much more di cult. The reason for this is that the dtex of most PA yarns is finer compared to PES fibers, further the low yarn tension with ner dtex causes the pane surface to be polished. To slow down this polishing process, Temco developed a PU disc with nano technology, the NanoDisc.