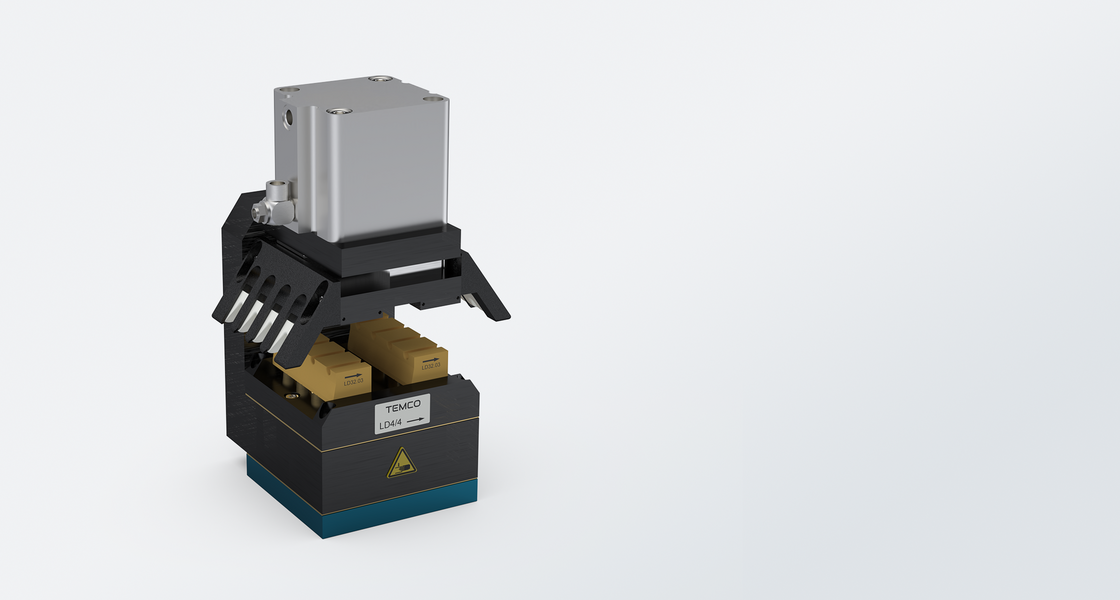

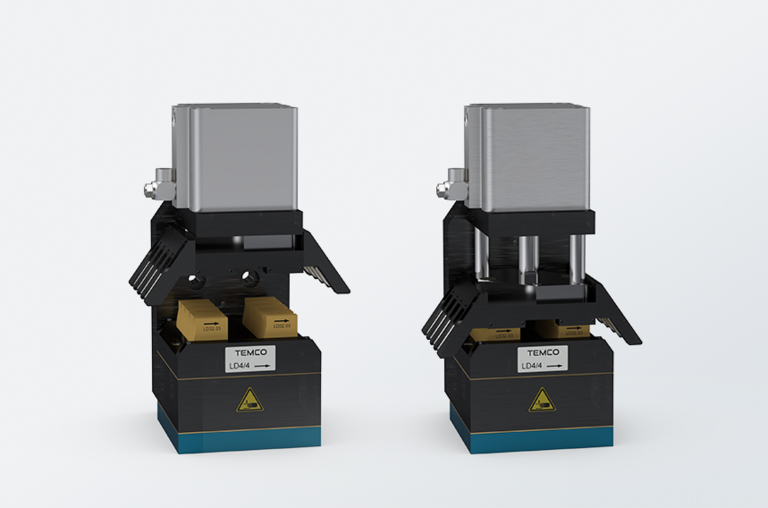

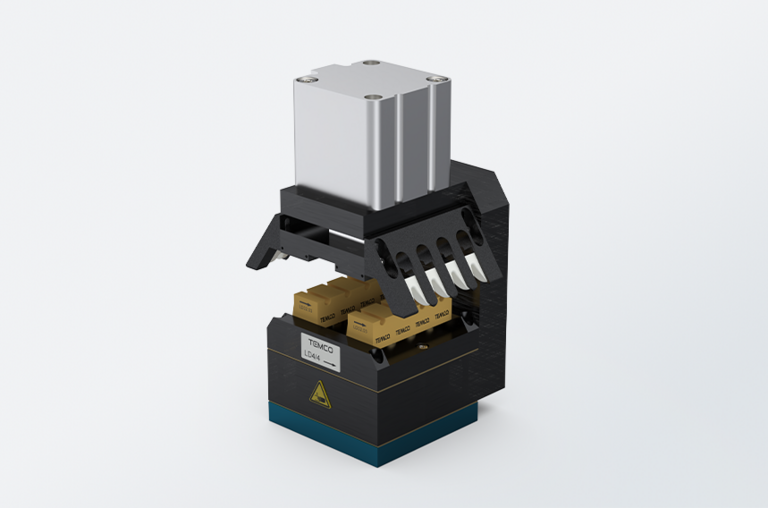

Thanks to the tandem layout of the air interlacing jet LD4, it is possible to optimize the tangling effect, even at highest yarn speeds.

The LD4, which incorporates the field-proven engineering and technology of the LD32 jet, has been especially designed for high-duty Bulked Continuous Filament (BCF) installations. It can also operate on other machines to produce Continuous Filament (CF) yarn, Partially Oriented Yarn (POY), Fully Drawn Yarn (FDY) and Highly Oriented Yarn (HOY).

Yarn speeds of up to 7 000 m/min can be achieved depending on the yarn type and requirements placed on the tangling quality. This results in an increase of approximately 50% compared to the LD32.

With amortization in just under six months, the LD4 jets are an appealing and cost-effective investment.