In the carding machine the fibers are processed in a narrow gap between two rotating components. It is essential to maintain a high precision to the critical dimension parts like flexible bend, flat rods and sliver measuring unit.

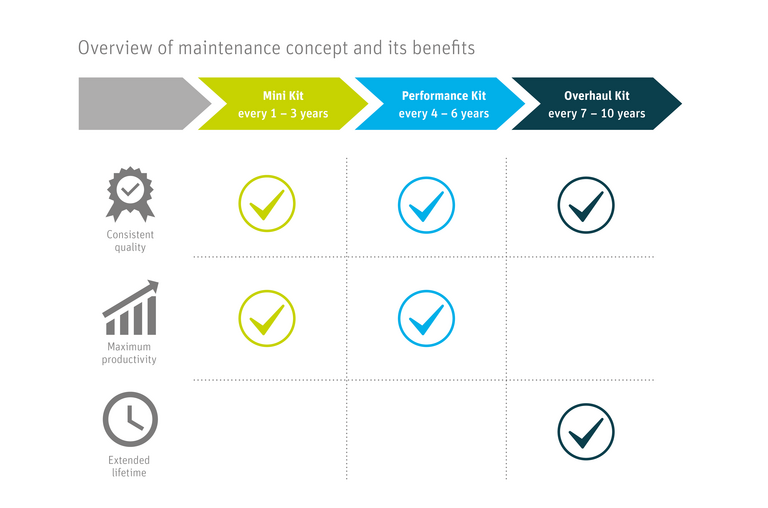

The card overhaul kit includes these key critical components that contribute to quality and production. This kit extends the machine’s lifetime to several years while maintaining its original performance. It comes with two optional packages, which allow customers to customize the kit based on their requirements.

Customer values

- Reducing sliver breaks

- Improving sliver evenness and uniformity

- Achieving uniform material feed from chute to the card

- Extending lifetime of machine and parts