Why Rieter Draw Frames Are First Choice for Spinning Mills

Rieter has been synonymous with excellence in draw frame technology for decades, setting the benchmark for highest sliver quality at maximum delivery speeds. With nearly 50 000 draw frames shipped worldwide in the last 40 years, Rieter continues to shape the spinning industry with its innovative strength and know-how.

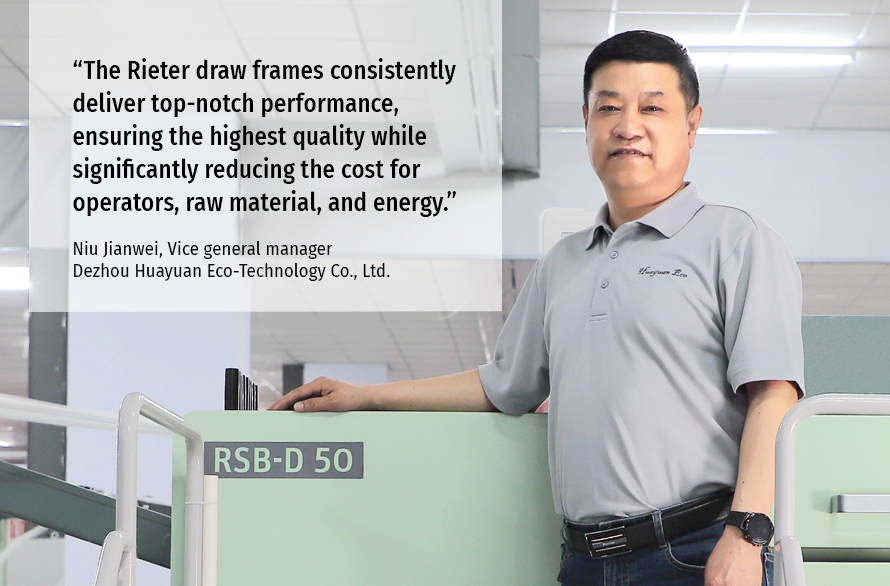

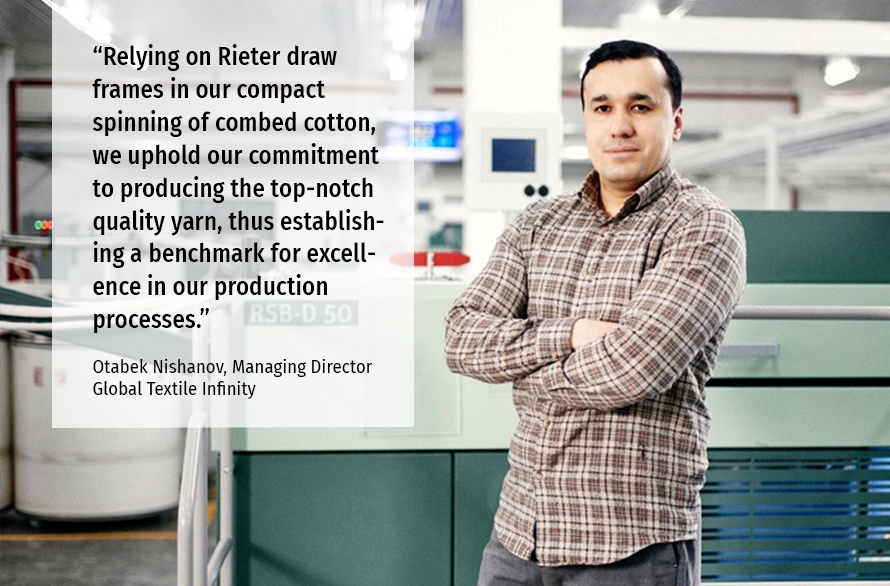

A consistent and uniform sliver is a prerequisite for quality consistency in the yarn. This is exactly what Rieter draw frames excel at. They stand for outstanding sliver quality at speeds of up to 1 200 m/min. The machine’s excellent scanning precision and highest dynamics are the secrets behind the superb autoleveling performance. The Rieter Quality Monitor (RQM) also plays an important role. It reliably prevents the production of faulty sliver.

I’ve never had to worry about the quality of my yarn, thanks to the unwavering consistency provided by the Rieter draw frame RSB-D 26.Wang Jiaxiu, Owner, Shunyuan Textile, China

Easy Handling and Minimized Workload

Rieter draw frames have fewer belts and drive elements compared to competitor machines. This not only reduces friction which in turn also cuts energy costs significantly, it also makes life easier for operators. This is a decisive feature for spinning mills.

With our Rieter single-head draw frames, we have increased our productivity and quality. We value its flexibility when we switch between various raw materials and blends.Maria Felix Villeda, Production Manager, Apparel Guatemala