Reconditioning Carding Flats Increases Lifetime and Productivity

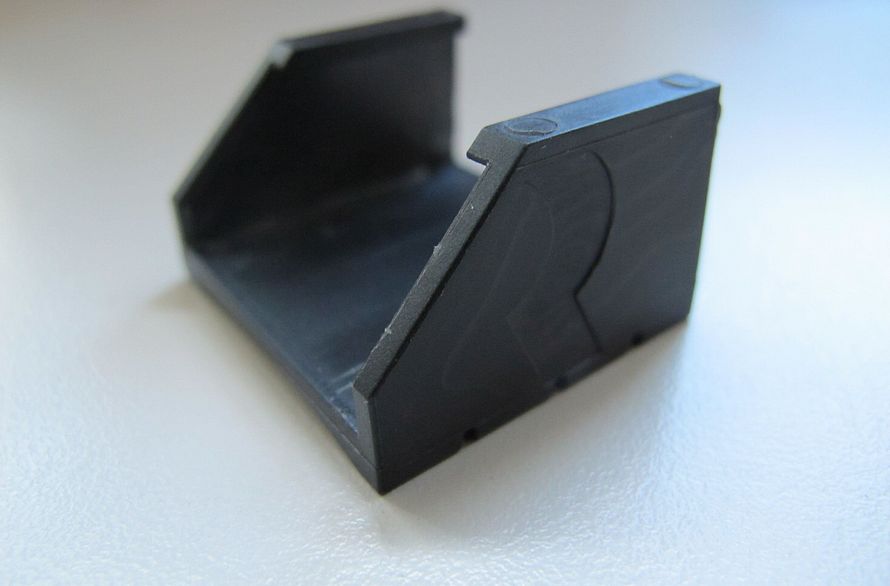

FlatCLIP fixed to the existing modified cast iron flat.

Having operated 12 Rieter cards C 50 since 1995, Madura Coats, India, approached Rieter’s After-Sales team with a request for a sustainable solution to increase the lifetime of the cards. The end sections of the cast iron flats had already exceeded their service life and had to be completely replaced. Rieter and Madura Coats together came up with the idea of incorporating the slide shoe concept from the new generation of cards into the older C 50 cards. Applying the latest slide shoe concept to existing machines helps to extend the machine life and improves productivity. Reusing the flats also prevented the disposal of more than four tons of cast iron, which helped the customer reach their environmental targets.

The Challenge

As the cards C 50 have been in operation for more than 28 years, the cast iron flats and flexible bends were eventually worn out, resulting in tolerance issues. The carding gap was ineffective due to multiple cycles of end milling on the flat heel and toe arrangement. As a result, the carding efficiency was reduced, leading to inferior sliver quality and, in some cases, reduced production. To address this issue and extend the lifetime of their equipment, Madura Coats started looking for a cost-effective and sustainable solution that would enable them to keep these machines in operation.

The Solution

Rieter’s repair services team took on the challenge of finding a cost-effective solution: reusing the existing cast iron flats and implementing the slide shoe concept which is a standard feature in new generation card machines. A comprehensive repair scope was offered to Madura Coats and it included the reconditioning of the existing flat rods to accommodate replaceable slide shoes FlatCLIP. In addition, the flexible bends were replaced and a graphite lubrication system was introduced, in order to ensure a smooth operation of the slide shoes.

The Customer’s Benefits

The repair solution offered by Rieter brings multiple advantages to the customer. The FlatCLIP slide shoe was precisely milled to achieve the proper heel and toe angles, allowing it to withstand two to three cycles of end milling, thus ensuring a consistent carding gap between the flats and the cylinder. As a result, the card performance was optimized, the sliver quality was improved and the machine productivity was restored. Additional benefits in terms of maintenance costs were introduced since the slide shoes can be easily replaced after three to four years of operation.

The introduction of the graphite lubrication system facilitates the smooth movement of the flat rods and helps extend the lifespan of the slide shoes and the flexible bends. This repair eliminates the need to replace the flat rods throughout the machine lifetime. In addition, through this repair, Rieter supports the Madura Coats vision of environmental sustainability by helping them save more than four tons of cast iron from being discarded as scrap.

The FlatCLIP from Rieter is an affordable and cost-effective solution to reuse the existing cast-iron flats in the best possible way. This prevents the disposal of waste and supports Coats’s commitment to sustainability. We are very happy with the performance and are sure it will be long-lasting. This repair also restored the quality of the sliver with an increase in productivity.A Ramkumar, Manufacturing Director of Madura Coats