Excellent Fiber and Spinning Preparation for High Quality and Efficiency in Air-Jet Spinning

Rieter cards and draw frames are not only the best preparation for ring and rotor yarns made of cotton, polyester and its blends. Also for viscose air-jet yarn, they are the perfect fit to prepare the sliver for any air-jet spinning machine. At the Chinese customer Guangxi Baisheng Textile Co., the Rieter cards and draw frames have a positive effect on the spinning efficiency as well as the quality of the air-jet yarn which can be seen right through to the end product.

The Challenge

Baisheng's business is the production and sale of colored ring and air-jet yarns and fabrics. Their fabric production requires 100 tons of yarn per day. As they can only produce 40 tons by themselves (22 tons of air-jet yarn and 18 tons of ring yarn), one goal is to maximize spinning production.

The yarn produced by Baisheng is used for high-end knitting applications and fabric defects have to reduced as much as possible. Excellent fiber preparation and spinning preparation support the production of high-quality air-jet yarn and high spinning efficiency. In view of the increasingly competitive air-jet market, another of Baisheng's goals is to reduce conversion costs.

The Solution

The card C 72 with the proven 1.5 m carding technology and 32 active flats leads to excellent card sliver quality and high production. The precise carding gap across the entire width of the machine ensures that the specified settings are maintained during operation. The C 72 fully separates the tufts into single fibers and reduces neps to a minimum.

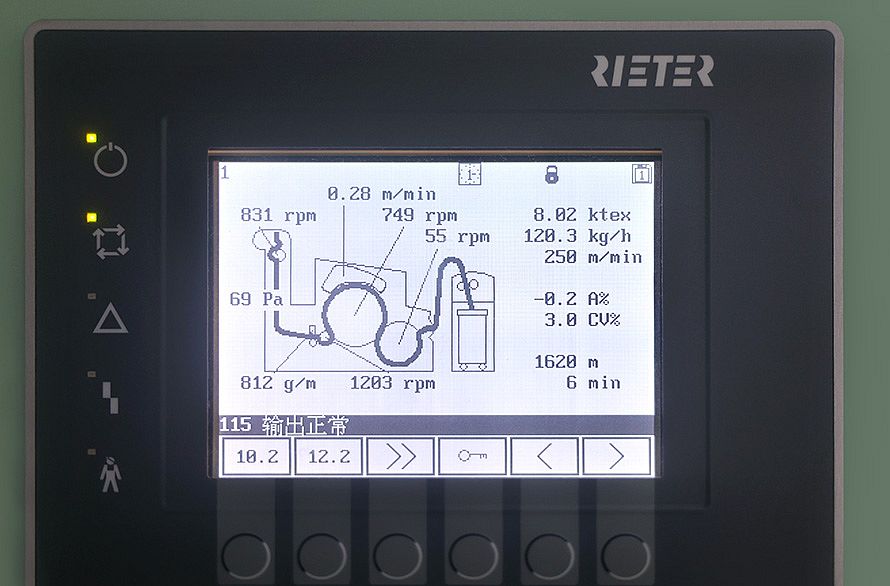

The autoleveler draw frame RSB-D 26c offers superb scanning precision and highest autoleveling dynamics. It provides a sliver with complete parallelization and highest evenness which is perfectly suited for processing on air-jet spinning machines. A unique and patented solution ensures exact sliver coiling form the first meter. A contact-free precision light barrier detects when the first sliver coils contacts the coiler and only then switches the machine from the slow mode to full production speed. The Rieter Quality Monitor (RQM) continuously monitors the thickness of the delivered sliver and stops the draw frame if the predetermined limits are exceeded.

The Customer’s Benefit

At Baisheng, the output of the cards C 72 reaches 120 kg/h. This is 20-33% higher than the production of other cards which run with the same application. The delivery speed of the autoleveler draw frame RSB-D 26c reaches 580 m/min. The controlled sliver coiling contributes to high quality and high raw material yield while reducing energy consumption.

Compared to other draw frames, the annual energy saving per line with three draw frame passages is up to 22 932 RMB. On top, the integrated RQM reliably prevents the production of faulty sliver.

The output of the Rieter cards and draw frames exceeded my expectations and the industry average level. The excellent quality of the card sliver and the autoleveling dynamics of the draw frame guarantee efficient and high-quality production in end spinning. I am also impressed by the energy-saving design of the Rieter draw frames.Zhan Yiyu, Chairman of Guangxi Baisheng Textile Co., Ltd.

Download

About Guangxi Baisheng Textile Co., Ltd.

Guangxi Baisheng Textile Co., Ltd. was established in 2018 and mainly produces Ne 16-40 viscose ring yarn and air-jet yarn for processing knitwear. In addition to the spinning process, Baisheng also owns the covering, doubling, dyeing, flat knitting and other processes. By vertically integrating the industrial chain, Baisheng can achieve more profitability and maintain its competitiveness in the market.