Customized, Energy- and Cost-Saving Automation with Autoconer X6 Multilink

MKAS Textile Pvt. Ltd. is a newly established spinning mill in the Indian textile industry. The company has been in the fine yarn spinning business since 2021 and is working with a production capacity of 4.5 tons per day. It sells 100% cotton yarns made from high-quality cotton fibers like PIMA, GIZA, in the yarn count range between Ne 80 to 100 for weaving applications. To increase profitability and to reduce the dependence on skilled personnel, the spinning mill decided to install the winding machine Autoconer X6, type V Multilink as a highly economical, energy-saving automation solution.

The Challenge

Given the limited resources like skilled operators and high-quality raw material, it is a major challenge to ensure a consistently high level of quality. Rising energy costs make it difficult to work with acceptable production costs for the demanding requirements of the market.

The Solution

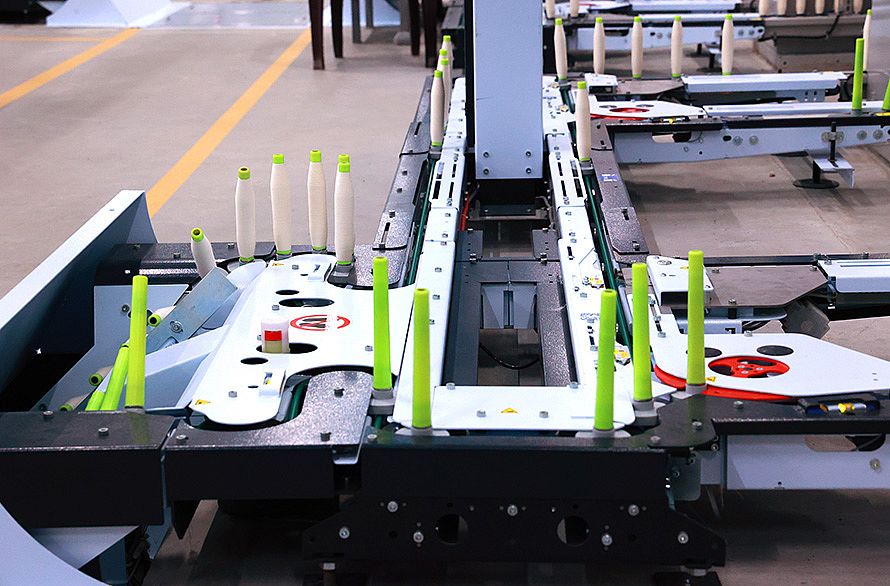

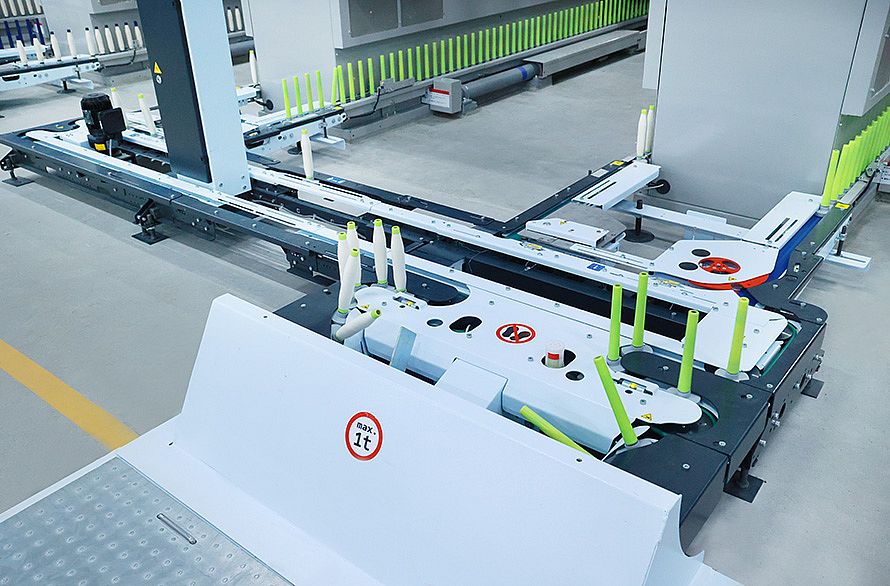

MKAS Textile Pvt. Ltd. opted for a high degree of automation with the Autoconer X6 Multilink system. To plan the most effective and optimal spinning mill layout, Rieter experts discussed the requirements with the management and technicians. Due to the attractive benefit on investment costs and operating costs, MKAS opted for eight winding machines Autoconer X6, type V with automatic material flow as 2:1 Multilink (52 winding units each). This means that two ring spinning machines are linked to one Autoconer. To respond to MKAS Textile’s individual needs for maximum space utilization one winding machine was added as 1:1 direct single-link (26 winding units). As specification, the company chose the underfloor link where the cops and spinning tubes move underground between the ring spinning machine to the winding machine. This creates a passageway for operators between the two machines and a very manageable machine installation.

The Customer's Benefits

Now, the spinning mill is running in full production, and MKAS Textile Pvt. Ltd. is very satisfied with its decision to go with Autoconer X6, type V Multilink.

The investment costs of 2:1 Multilink mill installation of 442 winding units (tailored to their layout specification), were significantly lower than as 1:1 direct single-link of 442 winding units, due to optimum quantities of machines, components or aggregates.

Recently, MKAS Textile Pvt. Ltd. conducted an energy study comparing their 1:1 single-link machine and 2:1 Multilink system. Around 25% lower energy consumption in favor of the Multilink machines was measured. This means a saving of 238 750 kWh/year, which corresponds to an annual energy cost saving of 1 910 000 INR (based on their daily production of 4,5 tons, 362 working days/year, and 8 INR/kWh).

Furthermore, the Multilink system achieves major benefits in terms of labor saving thanks to the longer winding machines and optimized mill layout. Instead of four operators, only two operators can now manage the tasks for the eight Multilink winding machines: i.e., one operator can handle four Autoconer’s (7 296 ring spinning spindle production), which means a doubling of their working area.

In addition to these impressive monetary facts, MKAS Textile Pvt. Ltd. underlines the user-friendliness for its operators by the underfloor link system. The SPID online quality monitoring system, also integrated as standard for Multilink, helps to monitor the yarn quality of each ring spinning spindle. This quality monitoring function in Multilink systems is available on the market only for the Rieter Autoconer. Thanks to the open prism technology, MKAS Textile Pvt. Ltd. achieves very good splice appearance and high splice strength. The combination of Autotense FX, Propack FX and the 3gg asym. drum type (for fine yarn count range) provides excellent package quality which ensures outstanding unwinding behavior in the downstream process and ultimately leads to high-quality fabrics.

We are highly satisfied with the Autoconer X6 Multilink installation. The lower investment costs and, above all, up to 25% lower energy costs in operation, are extremely important aspects for us, for a profitable business. This allows us to establish ourselves as a new spinning company with high-quality products in a difficult and demanding market.Mr. S. Mohamed Suhil, Managing Director MKAS Textile Pvt. Ltd.

Download

About MKAS Textile Pvt. Ltd.

MKAS Textile Pvt. Ltd. is a newly established spinning mill in the Indian textile industry. The company has been in the fine yarn spinning business since 2021 and has set up a production capacity of 4.5 tons per day. It works as a yarn seller, and sells 100% cotton yarns made from high-quality cotton fibers like PIMA, GIZA, in the yarn count range of Ne 80 to 100 for weaving applications. Customers are in the domestic market as well as abroad, for example in Bangladesh.