Card C 80: High-Quality Sliver Production at 120 kg/h

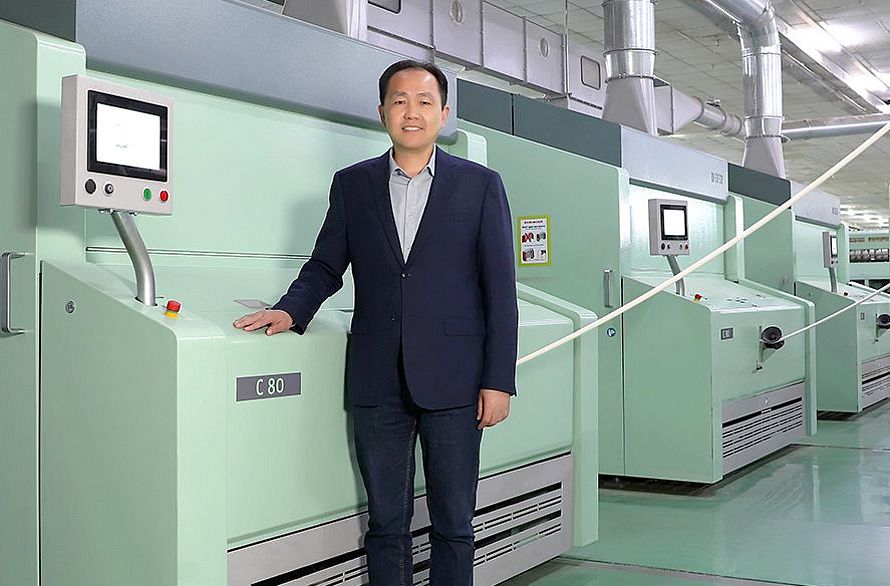

Chuzhou Jinshangjia Yarn Industry Co., Ltd. established in 2016 and located in Chuzhou, Anhui Province, operates with a spinning capacity of approximately 100 000 spindles. The company produces Ne 16-26 carded compact yarn, with a daily output of 55 tons. Jinshangjia’s mission is to optimize the cost-performance ratio of yarn while ensuring consistent, long-term quality. To further enhance production efficiency and meet quality standards, the company recently invested in three state-of-the-art Rieter cards C 80. At Jinshangjia, these machines deliver a production capacity of up to 120 kg/hour, maintaining excellent sliver quality.

The Challenge

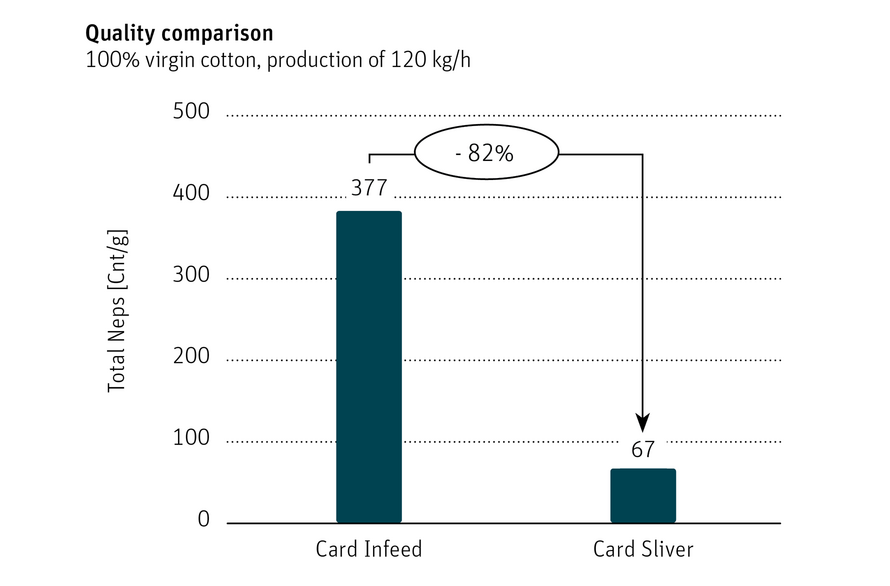

For many years, Jinshangjia has been committed to increase productivity and improve yarn quality to achieve the goal of cost reduction and quality improvement. With the existing cards C 72, the spinning mill produces 80 kg/h of sliver. To stay ahead in the competitive textile industry, Jinshangjia invests in state-of-the-art equipment. One challenge is to strictly control the sliver neps and increase production at the same time. In addition, it also faces the challenge of limited space.

The Solution

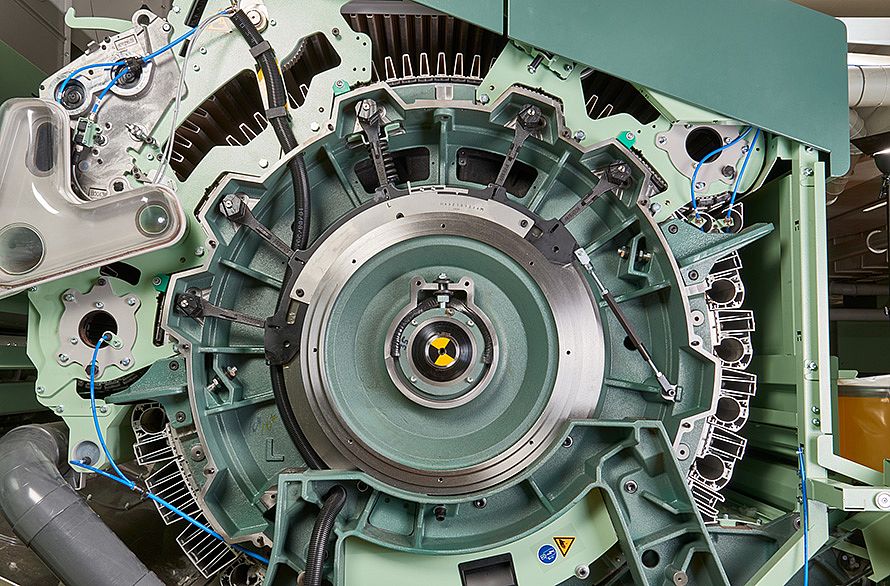

Jinshangjia decided to partner with Rieter once again to find a suitable solution. Rieter recommended the card C 80, widely recognized for its high production capacity, exceptional carding performance and advanced automation. The machine features the industry’s largest active carding area, which provides a strong basis for increased productivity. Moreover, the C 80 achieves remarkable energy efficiency by reducing machine requirements for high-capacity production, having an energy-optimized drive system and an enhanced suction technology. Equipped with 40 active flats and precise carding gap adjustments, the machine delivers outstanding sliver quality. Its modular design reduces maintenance efforts and minimizes downtime.

After conducting performance trials, Jinshangjia decided to dismantle some of its existing equipment and complement its fleet of Rieter C 70 and C 72 by investing in three new cards C 80.

The Customer's Benefits

The new investment has greatly increased the production capacity of Jinshangjia. The C 80 provides a consistent output of 120 kg/hour and maintains excellent sliver quality. This increased efficiency enables the company to accommodate higher order volumes without requiring additional floor space or increasing the number of cards. Furthermore, the C 80 ensures stable sliver quality while significantly reducing production costs per unit, optimizing both productivity and cost-effectiveness.

Our cooperation with Rieter dates back to 2013. For more than a decade, we have relied on Rieter’s equipment, advanced technology and professional service. The card C 80 is characterized by high stability, remarkable production efficiency and a long service life. The sliver is of superior quality, with fewer neps, ensuring excellent yarn quality in the endspinning process. This is highly appreciated by our customers.Gu Jingguo, General Manager of Chuzhou Jinshangjia Yarn Industry Co., Ltd.

Download

Chuzhou Jinshangjia Yarn Industry Co. Ltd.

239000 Chuzhou City

China