Draw Frame Pneumatic Panel Refurbishment Improves Sliver Quality

Rieter draw frames are known for producing high-quality sliver.

Autoleveler draw frames are critical to the production of high-quality sliver. Rieter’s pneumatic panel refurbishment enables superior machine performance and consistent sliver quality. The new configurable digital pressure monitoring system helps to address the key issue of sliver count variation caused by inconsistent pressure regulation.

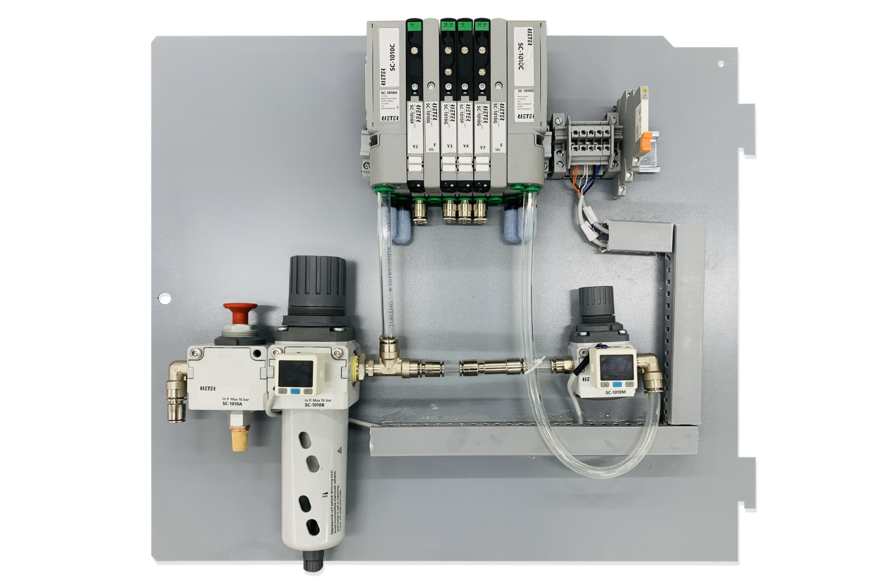

In the spinning process, the draw frame is an indispensable asset, playing a crucial role in the production of high-quality sliver. Central to the optimal performance of draw frames is the pneumatic panel arrangement. The panel regulates the functional components so that the quality of the sliver is consistent and the machine can run at higher efficiency. Rieter After Sales offers pneumatic panel refurbishments for autoleveler draw frames RSB-D 30, D 35, D 40 and D 45. This service ensures superior and consistent machine performance.

Consistent pressure monitoring for uniform sliver quality

The demand for high-quality yarn necessitates the flawless operation of autoleveler draw frames. However, several challenges can compromise their efficiency. Aged pneumatic components are prone to leaks and failures, which can lead to sliver count variation, halt production and increase maintenance needs. The RSB pneumatic panel refurbishment service replaces these aging parts with new, durable components, ensuring consistent performance and reduced downtime. The refurbishment service includes configurable digital pressure monitoring systems for both scanning roller and inlet pressure. These systems continuously monitor the pressure and stop the machines promptly in case of variations in the set pressure, ensuring no faulty sliver is produced due to pressure fluctuations.

The scanning rollers are the key components in measuring the variations in the feed sliver of every RSB draw frame. These scanning rollers are loaded by a pneumatic system. It is important to monitor and measure the air pressure to ensure the proper functioning of the scanning rollers. The digital pressure indicator (DPI) in the refurbished pneumatic panel monitors the actual pressure level and communicates with the machine control system. The programmed relay output stops the machine when the pressure is either above or below the defined limit. This helps to measure the sliver variation efficiently by the scanning rollers at a constant load, thereby minimizing the sliver count variations and enhancing its quality. The refurbished panel can be easily installed by a customer’s service technician and requires little maintenance.

Higher flexibility with lower investment costs

The modular design of the pneumatic panel ensures easy integration which makes it a cost-effective solution. The refurbished pneumatic panel is designed to withstand vibrations, shocks and wide temperature variations. Built with durable technology and low-maintenance components, the refurbished panel reduces the need for frequent repairs and replacements, thereby lowering long-term maintenance costs. Investing in the pneumatic panel refurbishment for the RSB draw frames is a strategic decision that promises immediate and long-term benefits. The refurbishment improves operational efficiency and product quality, thereby reducing downtime and maintenance costs.

We have refurbished the pneumatic panel of our seven RSB draw frames as per Rieter’s recommendation. Continuous digital pressure monitoring at the machine inlet and scanning rollers helps precise measurement of sliver variation. The machine stops in case of pressure variations, ensuring a uniform sliver is produced.V Saravanan, General Manager, Sri Shanmugavel Spinning Mills (Unit-1), India.