Product details

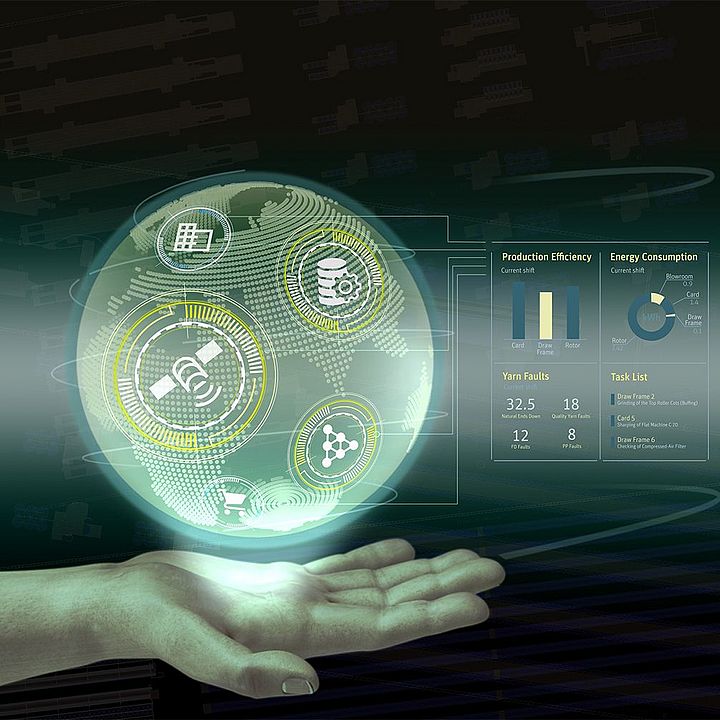

The fully automatic rotor spinning machine R 70 sets new standards in terms of its high productivity, improved raw material utilization and low energy consumption. State-of-the-art automation technology at each spinning position increases efficiency and flexibility and is also the basis for low energy requirements.

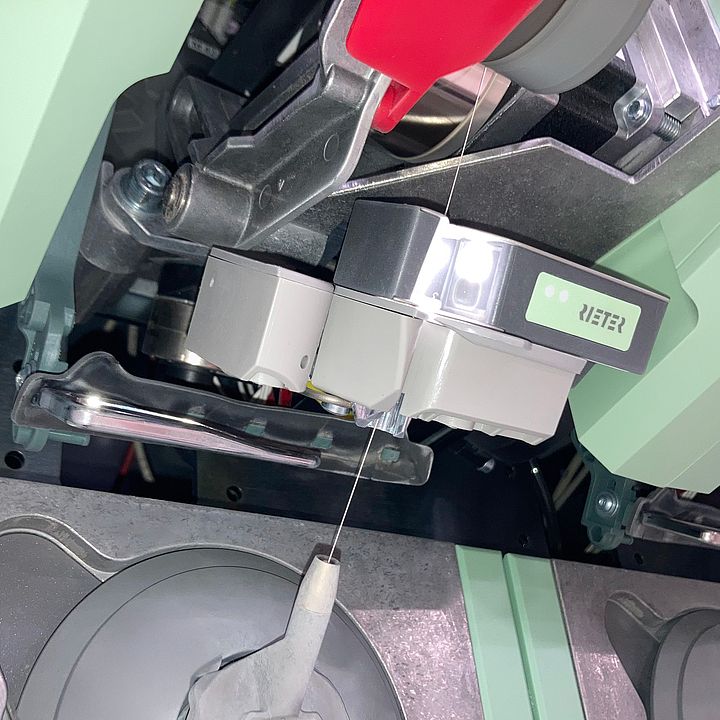

The advanced spinning box of the R 70 ensures high spinning stability and yarn tenacity. The BYpass and rotor cleaning with each piecing operation makes it possible to spin slivers with high trash content. The uniform yarn quality with yarn-like piecings provides the best results for further processing.