Nipaş Revolutionizes Yarn Production with TUCAN Metallic Card Clothing

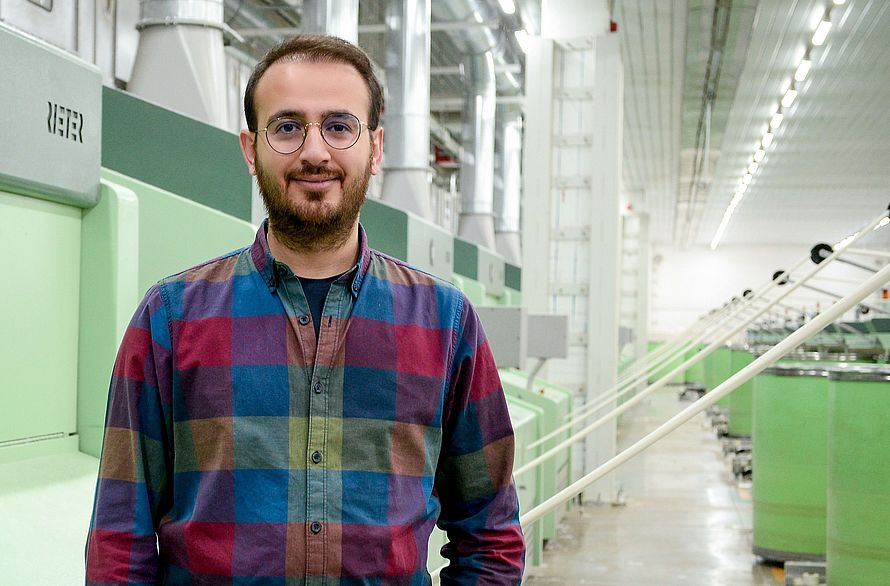

Ömer Mutlu, Mills Manager, Nipaş Tekstil says Nipaş Revolutionizes Yarn Production with TUCAN Card Clothing for Spinning

When Nipaş Tekstil, a major yarn manufacturer based in Turkey, wanted to minimize downtime in its production process and increase efficiency, they decided trial Graf’s TUCAN metallic card clothing. Processing 1 000 tons of yarn of Ne 30 cotton showed that TUCAN’s grinding- and maintenance-free operation increases overall profitability and ensures consistent high yarn quality. The company has now adopted TUCAN on its production lines.

The challenge – driving efficiencies whilst maintaining quality

Nipaş Tekstil realized that reducing the frequent maintenance and resulting production stoppages on its Ne 30 cotton yarn production line could help to maintain competitiveness and reduce operational costs – but only if any changes continued to deliver the consistently high yarn quality they are renowned for.

Introducing Graf TUCAN - grinding-free operation on over 1 000 tons of fibers

Nipaş installed TUCAN Metallic Card Clothing on their Rieter card. The TUCAN carding wire, designed with innovative Swiss Engineered tooth geometry, features a long tooth backbone and elongated tip back. This advanced design ensures superior fiber guidance, lifting fibers upward during the carding process, which results in better fiber control, fewer neps and more consistent yarn quality.

Trials with 100% cotton produced a yarn of Ne 30 count showed excellent results early on. After processing 1 000 tons of fibers, Nipaş confirmed that TUCAN’s grinding-free technology had significantly improved production efficiency and quality consistency. The solution also supports cotton and blends up to yarn count Ne 60, providing a versatile and reliable system for a wide range of production requirements.

TUCAN Metallic Card Clothing has completely transformed our carding process. Even after processing 1 000 tons of fibers, we have consistently achieved superior yarn quality without the need for grinding. This technology has significantly reduced our downtime and operating costs while enhancing efficiency.Ömer Mutlu, Mills Manager at Nipaş Tekstil

Five significant benefits for ease of production, costs and quality

As a result of installing TUCAN’s Metallic Card Clothing, Nipaş Tekstil achieved continuous high-quality yarn production without maintenance interruptions. Today, Nipaş Tekstil benefits from the following:

- Grinding-free performance: Processing 1 000 tons of material without the need for grinding of the carding wires ensures uninterrupted production, eliminates the need for specialized grinding equipment and reduces costly downtime.

- Maintenance-free operation: TUCAN’s carding technology removes all maintenance requirements, further minimizing operational interruptions.

- Cost savings: By eliminating the need for grinding, Nipaş saves significantly on labor and operational costs, increasing overall profitability.

- Risk minimization: The potential risks of suboptimal settings leading to additional maintenance are reduced.

- Compatibility of the wire: The TUCAN carding wire is compatible with all different card types.

- Consistent yarn quality over time: The carding wires maintain optimal and constant yarn imperfections, ensuring that yarn quality remains high throughout the production process.