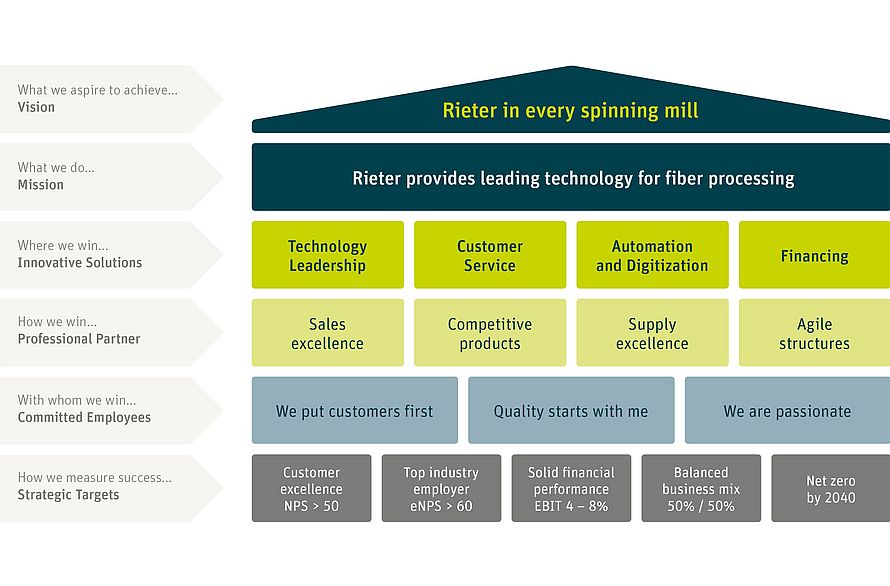

Group Strategy

Vision

Rieter’s cutting-edge technology powers every spinning mill. Wherever textiles are produced, Rieter machines, systems, components and expertise come into play. Every apparel item, home furnishing fabric and technical textile is shaped by Rieter during the manufacturing process, minimizing resource consumption and maximizing performance. As market leader, more than 3 000 customers rely on Rieter technology every day to achieve more with less. This gives them the edge they need to compete and win.

Mission

Rieter provides leading technology for fiber processing. Pioneering, innovative and sustainable, Rieter continuously pushes boundaries and sets new standards. The company’s textile technologists are the industry’s best and brightest. Building on 230 years of experience, Rieter’s unmatched expertise in processing fibers to yarn sets the standard for the next generation of smarter, more efficient and sustainable spinning technology.

Innovative Solutions

Rieter wins with innovative solutions. Thanks to outstanding sales and customer service as well as supply excellence and agility, the company is able to create added value for its customers and occupy a leading position in the industry.

Rieter is a technology leader, setting the pace for innovation in the spinning sector. As the only systems provider covering all process steps, Rieter’s expertise in converting fiber to yarn puts it at the forefront of the industry. With Rieter technology, spinning mills are able to maximize resource efficiency and minimize cost conversion, while achieving higher yarn quality. The company manages its technology portfolio actively through strategic product power hubs, and develops worldclass engineering for real-world requirements where customers are located. The Campus in Winterthur is Rieter’s research and innovation hub and home to the industry’s largest development and technology center.

Rieter is a customer-service champion. The company puts a laser-sharp focus on customer success, so mills can get the most out of their machines. Through a well-established after-sales network around the world, customers have access from any place and at any time to high quality spare parts and components, as well as maintenance and repair services. This enables them to optimize their machine utilization 24/7 and rely on minimal downtime and prompt repair and technical support. The company’s state-of-the-art webshop features more than 15 million spare parts with a personalized ordering experience.

The future of the spinning industry is automated, digital and smart. As mills struggle to hire and retain workers, automation technology is essential in order to ensure consistent and efficient operations. Rieter has stepped up its R&D activities to fully automate the value stream by 2027 through autonomous transport systems and collaborative robotics. Rieter’s digital spinning suite ESSENTIAL will be the command-and-control center of smart and high-performing mills that lower cost and maximize returns. Customers will be able to fully focus on their yarn business by outsourcing their operations to Rieter technology and expertise. Investment in spinning mills is expensive, making financing a differentiator. Rieter builds on its advantage as a global company with Swiss roots to offer customers attractive financing packages designed to fuel their growth.

Professional Partner

Rieter wins through professionalism, making it the partner of choice for customers and suppliers.

In the pursuit of sales excellence, Rieter’s organizational structure is designed around customer requirements. The company stays ahead of market trends in order to seize growth opportunities when they arise, underpinned by a smart global sales footprint.

Rieter is a technology leader at a competitive cost. The company is committed to providing its customers with the greatest value for their investment.

Supply excellence drives Rieter’s industry-leading technology. High quality, on-time delivery, first-pass yield and strong claim management are at the core of the company’s supplier partnerships.

Agility is the key to success given the cyclical nature of Rieter’s markets. The organizational structure is designed to be lean, fast and agile in order to respond quickly and flexibly to any change in the market.

Committed employees

Rieter’s employees are its greatest asset. The can-do spirit, dedication and drive of the company’s employees make all the difference to customers, shareholders and the communities in which Rieter operates. The following company values inspire them in their daily work:

| “We put customers first” | At Rieter, customer-centricity is an integral part of the company’s DNA. |

| “Quality starts with me” | As a company with Swiss roots, Rieter is held to the highest quality standards. The Rieter team is on a mission to meet and beat those expectations every day. |

| “We are passionate” | At Rieter, everyone is united by a deep passion to enable customer success. |

Strategic targets

What gets measured, gets done. Five strategic targets define success:

| Net Promoter Score (NPS) > 50 | Customer excellence is defined by a Net Promoter Score above 50. |

| Employee Net Promoter Score (eNPS) > 60 | Rieter aims to become a top industry employer defined by an eNPS above 60, which beats the industry benchmark. The company provides a diverse, equitable and inclusive environment in which employees thrive, thus helping to attract and retain top talent. |

| EBIT 4 – 8% | Even in tough years, Rieter is committed to achieving a solid financial performance with an average EBIT of between 4 and 8%. |

| Balanced business mix 50% / 50% | Rieter ensures a balance between its Machines & Systems Division as well as its After Sales and Components Divisions. |

| Net zero by 2040 | Rieter is playing its part in decarbonization. In line with the Science Based Targets initiative, Rieter aims to achieve net zero emissions by 2040. |